Recessed Bathroom Shelf

Built into the wall just like a window, this shelf unit offers additional storage without taking up any extra space, helping to keep the bathroom looking spacious and clutter free. Made of MDF, the unit measures 26 1/2″ wide by 42″ high (30 1/2″ by 46″ with its frame). It is assembled in part using wood biscuits.

The shelves shown in the photo have been built into a wall that opens into a closet on the other side, which means that they are actually deeper than the wall is thick. The measurements given in this guide are for shelves 4″ deep, which can thus be fitted into a regular interior wall. The back of the shelf unit is closed off with a sheet of Masonite.

Cut List:

ASSEMBLING FURNITURE WITH WOOD BISCUITS

This sturdy method of assembly involves inserting thin slices of compressed wood (“biscuits”) into slots made with a plate (or biscuit) joiner. When the biscuits come into contact with glue applied in the slots, they swell and stay wedged in place, holding the construction together. Once you have taken the time to learn how to use a biscuit joiner, the specialized tool required for this type of assembly,

you will find it a quick and easy technique.

Preparation

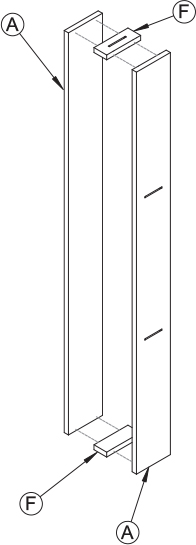

Vertical sides (A): Make the slots for the biscuits 13 1/4″

from each end of A, on one side only.

Spacers (F): Make the slots for the biscuits

in the very centre of the parts, i.e. 3/4″ from the edge.

Top / Bottom (G): Make the slots for the biscuits

in the very centre, i.e. 13 1/4″ from one of the ends.

Assembly

The shelf cubbies are formed by building individual “boxes” which are assembled with nails

and then fastened to each other using wood biscuits. Always apply glue to the inside of the slots before inserting the biscuits. Glue must also be applied to all the surfaces to be joined.

Assemble a vertical module by gluing and nailing two spacers F between two vertical sides A, one spacer at each end. All surfaces with slots should be facing outwards.

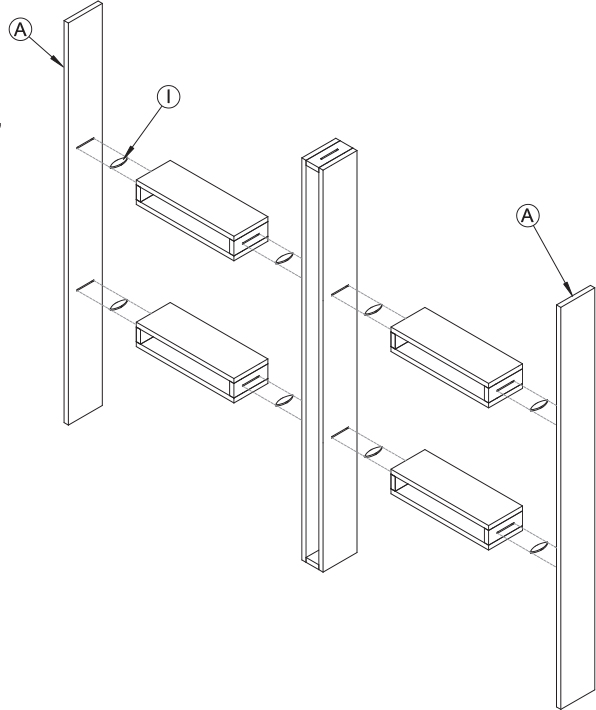

Assemble each of the four horizontal modules by gluing and nailing two spacers F between two horizontal sides C, one spacer at each end. All surfaces with slots should be facing outwards.

Assemble each of the four horizontal modules by gluing and nailing two spacers F between two horizontal sides C, one spacer at each end. All surfaces with slots should be facing outwards.

Fasten two horizontal modules between a side A and the vertical module, then do the same on the other side. Insert more spacers into the vertical module as needed, to prevent its sides from bending inwards. Hold in place with clamps and go straight on to the next step.

Fasten two horizontal modules between a side A and the vertical module, then do the same on the other side. Insert more spacers into the vertical module as needed, to prevent its sides from bending inwards. Hold in place with clamps and go straight on to the next step.

Apply glue to the slots in top / bottom G and to the ends of sides A. Insert the biscuits into the slots, then nail top / bottom G to sides A.

Apply glue to the slots in top / bottom G and to the ends of sides A. Insert the biscuits into the slots, then nail top / bottom G to sides A.

Glue and nail panel E to the back of the shelves.

Glue and nail panel E to the back of the shelves.

Glue and nail one vertical facade B to the front of the vertical module and fasten short horizontal facades D to the horizontal modules in the same way.

Glue and nail one vertical facade B to the front of the vertical module and fasten short horizontal facades D to the horizontal modules in the same way.

Insert the shelf unit into the wall opening, resting it on the bottom girt. Check for level, then screw into the studs.

Insert the shelf unit into the wall opening, resting it on the bottom girt. Check for level, then screw into the studs.

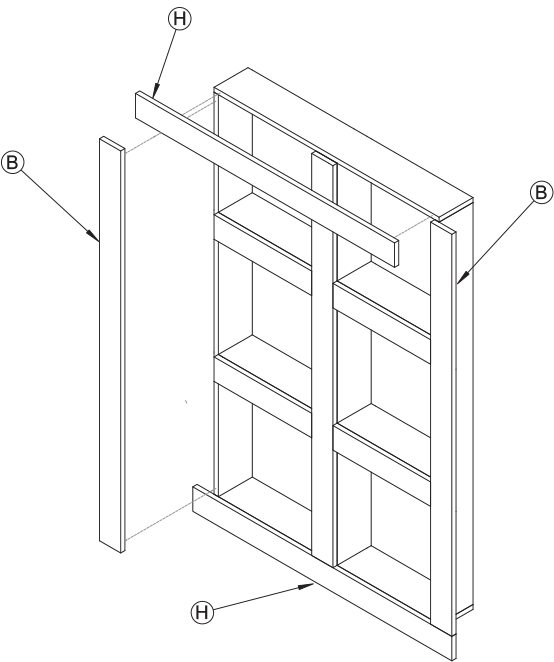

Glue and nail the two remaining vertical facades B and the two long horizontal facades H to the edges of the shelf unit in order to form a frame to conceal the cuts in the drywall. Fill the holes and apply a coat of primer. Paint.

Glue and nail the two remaining vertical facades B and the two long horizontal facades H to the edges of the shelf unit in order to form a frame to conceal the cuts in the drywall. Fill the holes and apply a coat of primer. Paint.

The original plan can be found at https://www.rona.ca