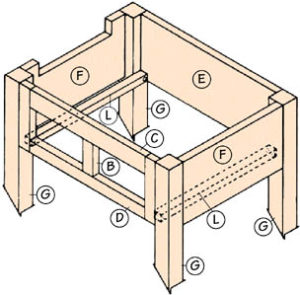

Bar Cabinet

- 1 – 1×2 at 4’

- 2 – 1×3 at 8’

- 10 – 1×4 at 8’

- 1 sheet of ½” plywood

- 1 half sheet of ¾” plywood

- 1 sheet of ¾” plywood

- 1″ Pocket Hole Screws

- 1-1/4″ Pocket Hole Screws

- 1-1/4″ Wood Screws

- 1-1/4″ Brad Nails

- Edge banding

- 1 set of 22” drawer slides (side mount with 1/2″ clearance)

- 1 set of Hinges

- 2 Drawer/Cabinet Pull

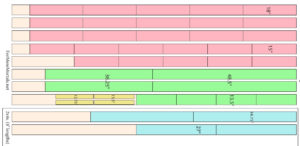

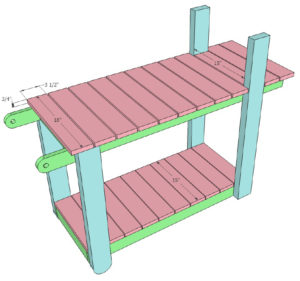

- 4 – 1×4 at 41-1/4” – Side Legs

- 6 – 1×4 at 16” – Side Frames

- 4 – 1/2” plywood at 13-3/8” x 16” – Side Panels

- 3 – 1×4 at 35-1/2” – Front Frame

- 2 – 1×4 at 41-1/4” – Front Legs

- 2 – 1/2” plywood at 13-3/8” x 35-1/2” – Front Panels

- 2 – 1×4 at 37” – Back Stretchers

- 2 – 1×4 at 37-3/4” – Back Legs

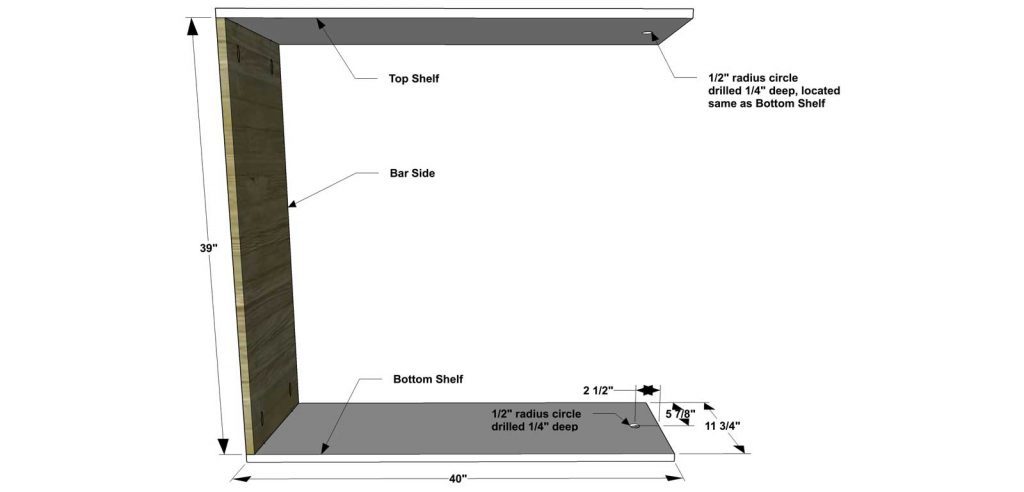

- 1 – ¾” plywood at 22-1/4” x 42-1/2” – Bottom Shelf

- 1 – 1×3 at 26-3/4” – Cabinet Divider

- 1 – ¾” plywood at 22-1/4” x 29-3/8” – Divider

- 1 – ¾” plywood at 20-1/2” x 22-1/4” – Shelf

- 1 – ¾” plywood at 21-1/4” x 22-1/4” – Shelf

- 1 – 1×2 at 17-3/4” – Drawer Stretcher

- 1 – 1×2 at 22-1/4” – Drawer Slide Spacer

- 1 – ¾” plywood at 22-1/4” x 42-1/2” – Countertop

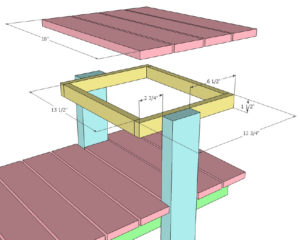

- 2 – 1×4 at 22-1/4” – Inner Top Spacers

- 1 – 1×4 at 37” – Inner Top Spacer

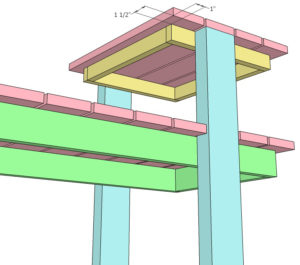

- 2 – 1×4 at 6-3/4” – Top Frame Back

- 3 – 1×4 at 3-1/4” – Top Frame Spacers

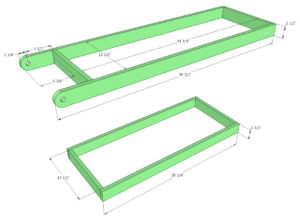

- 2 – 1×4 at 26-1/4” – Top Frame Sides

- 1 – 1×4 at 50-1/2” – Top Frame Front

- 1 – ¾” plywood at 27-3/4” x 50-1/2” – Top

- 1 – ¾” plywood at 15-1/4” x 20-1/2” Drawer Bottom

- 2 – 1×4 at 20-1/2” – Drawer Box Sides

- 2 – 1×4 at 16-3/4” – Drawer Box Front & Back

- 1 – ¾” plywood at 5-1/2” x 17-1/2” – Drawer Front

- 2 – 1×3 at 11-1/2” – Door Rails

- 2 – 1×3 at 26-1/2” – Door Stiles

- 1 – ½” plywood at 11-1/2” x 21-1/2” – Door Panel

Edge banding will be applied to the exposed edges of the plywood prior to assembly.

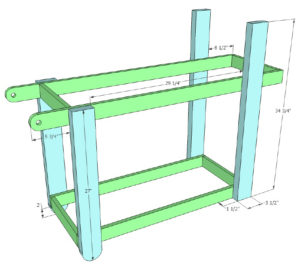

Cut the pieces for the legs, side frames, and side panels. Set the Kreg jig for ¾” material and drill pocket holes in each end of the frame pieces. Secure to the legs using glue and 1-1/4” pocket hole screws.

Set the Kreg jig for ½” material and drill pocket holes in all four edges of the panels. Secure to the legs and the frame pieces using glue and 1” pocket hole screws.

Cut the pieces for the legs, front frame, and panels. Set the Kreg jig for ¾” material and drill pocket holes in each end of the frame pieces, as well as one long edge of each leg. Secure to the legs using glue and 1-1/4” pocket hole screws.

Set the Kreg jig for ½” material and drill pocket holes in all four edges of the panels. Secure to the legs and the frame pieces using glue and 1” pocket hole screws.

Secure the entire front assembly to the sides using glue and 1-1/4” pocket hole screws.

Cut the pieces for the back legs and frame pieces. Set the Kreg jig for ¾” material and drill pocket holes in each end of the frame pieces. Secure to the legs using glue and 1-1/4” pocket hole screws.

Secure the back frame to the side legs using glue and 1-1/4” brad nails.

Cut the piece for the bottom shelf and drill pocket holes in all four edges. Secure to the lower frame pieces using glue and 1-1/4” pocket hole screws from the under side.

Cut the piece for the cabinet divider and drill pocket holes in each end. Secure to the back frame pieces using glue and 1-1/4” pocket hole screws.

Cut the piece for the divider and drill pocket holes in all four edges. Secure to the bottom, front frame, and cabinet divider using glue and 1-1/4” pocket hole screws. The back face of the divider (without pocket holes) will be flush with the back edge of the cabinet divider.

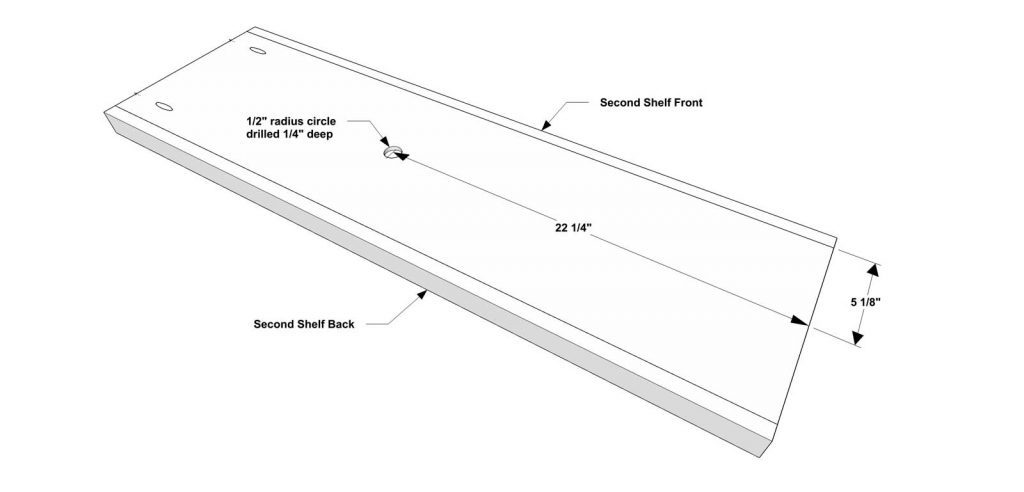

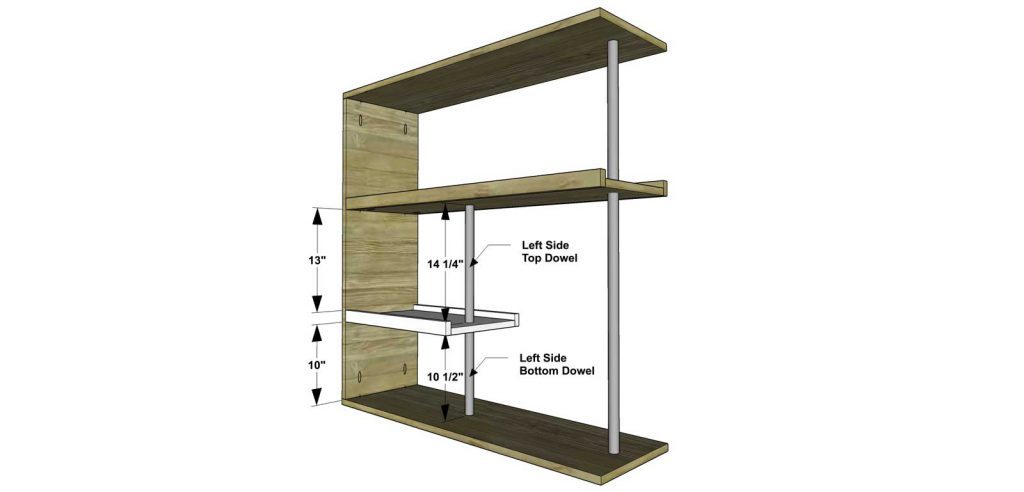

Cut the pieces for the shelves and drill pocket holes in the side and back edges. Position in each side of the cabinet and secure using glue and 1-1/4” pocket hole screws.

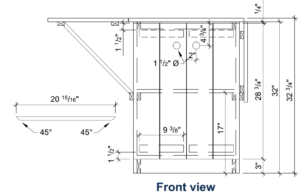

Cut the piece for the drawer divider and drill pocket holes in each end. Secure to the back leg and cabinet divider as shown using glue and 1-1/4” pocket hole screws.

Cut the piece for the drawer slide spacer and drill pocket holes in each end. Secure to the back leg and the front leg as shown using glue and 1-1/4” pocket hole screws. The bottom of the spacer will line up with the top of the drawer divider.

Cut the piece for the countertop and drill pocket holes in all four edges. Secure to the cabinet using glue and 1-1/4” brad nails through the legs and panels into the countertop. The top face of the countertop will be flush with the top face of the back frame. Add a few 1-1/4” pocket hole screws through the divider into the underside of the countertop.

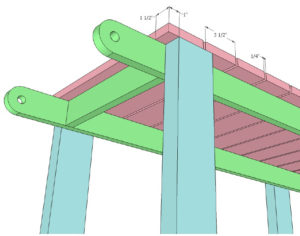

Cut the pieces for the inner top frame and drill pocket holes at one end as well as one long edge. Secure to the front panel and countertop as shown using glue and 1-1/4” pocket hole screws.

Cut the piece for the inner frame sides and drill pocket holes in each end as well as one long edge. Secure to the sides and countertop using glue and 1-1/4” pocket hole screws.

Cut the pieces for the top frame back. Secure to the side frame and inner top frame using glue and 1-1/4” brad nails.

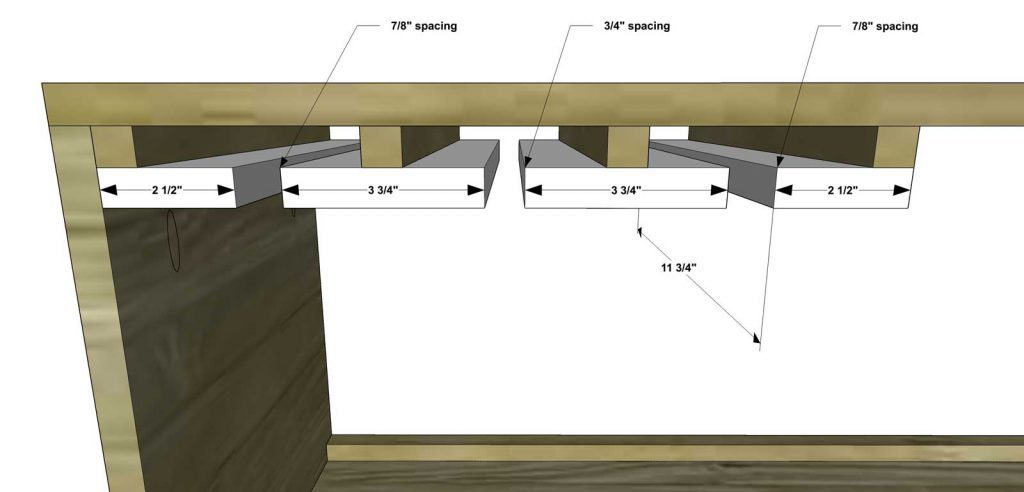

Cut the piece for the top frame spacers and drill pocket holes in one end. Secure to the front frame using glue and 1-1/4” pocket hole screws.

Cut the pieces for the top frame sides and drill pocket holes in one end. Secure to the back frame pieces using glue and 1-1/4” pocket hole screws.

Cut the piece for the top frame front. Position as shown then secure to the sides and spacers using glue and 1-1/4” brad nails.

Cut the piece for the top. Secure to the top frame using glue and 1-1/4” brad nails.

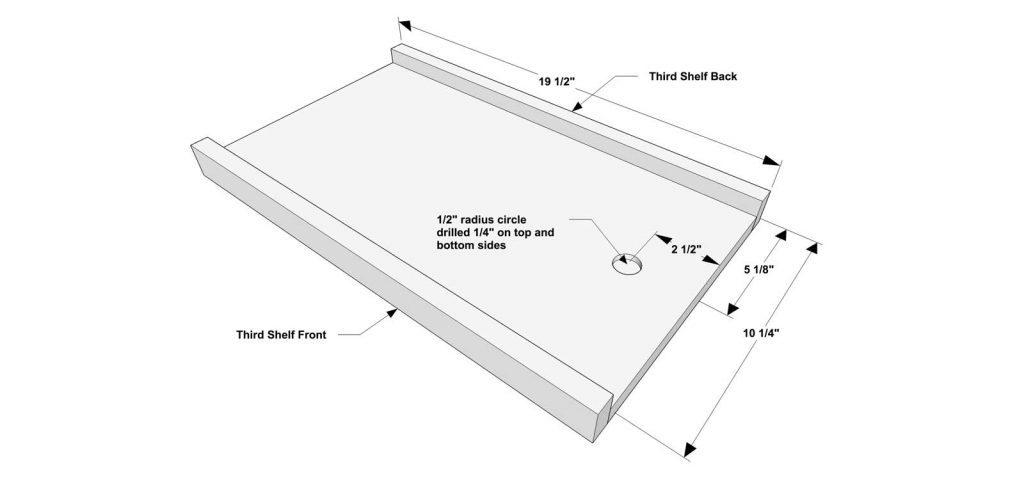

Cut the pieces for the drawer box. Drill pocket holes in all four edges of the bottom as well as each end of the sides. Assemble the drawer box as shown using glue and 1-1/4” pocket hole screws. Install the drawer slides according to the manufacturer’s installation instructions, locating them ¾” back from the front edge of the sides. Cut the pieces for the drawer front. Mark the position for the drawer pulls and drill the holes. Shim the drawer front in the opening – there will be a 1/8” gap around all sides – then drive screws through the holes for the drawer pulls into the drawer box. Open the drawer, and secure the drawer front using countersunk 1-1/4” screws from the inside. Remove the screws from the holes for the drawer pull then finish drilling the holes. Install the drawer pull.

Cut the pieces for the door. Drill pocket holes in each end of the rails then assemble the frame using glue and 1-1/4” pocket hole screws.

Cut the piece for the center panel. Set the Kreg jig for ½” material and drill pocket holes in all four edges. Secure the panel in the frame using glue and 1” pocket hole screws. The back face of the panel will be flush with the back face of the frame.

Install the hinges on the door, then install the door in the cabinet. Install the cabinet pull.

Fill any Screw, Nail or Pocket Holes, Sand and Finish as Desired

The original plan can be found out http://www.thedesignconfidential.com