Howell Bar Cabinet

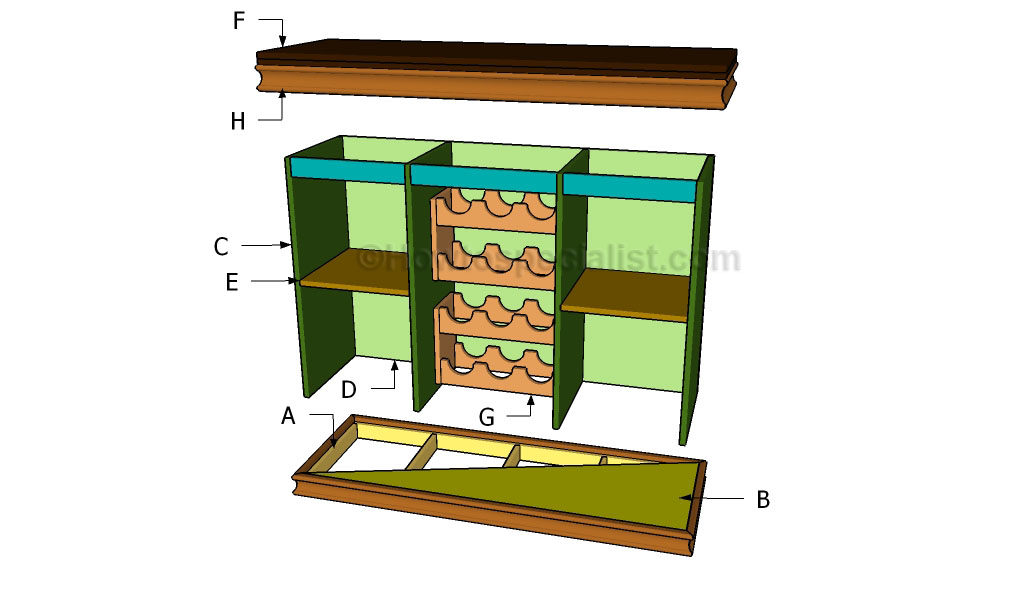

Like to entertain? This is a great bar cabinet for those get-togethers with friends! The DIY plans to build a Howell bar cabinet feature wine storage behind two doors with false drawer fronts, and a long pull-out cabinet in the center. There is plenty of storage for entertaining accessories and spirits in this cabinet!

- 1-1/4″ pocket hole screws

- 5/8″ brad nails

- 1-1/4″ brad nails

- Edge banding, optional

- 3 sets of 18″ ball-bearing drawer slides

- 2 sets of hinges

- 15 cabinet pulls

- Wood glue

- Sandpaper (100, 150, 220 grits)

- Finishing supplies (primer & paint, or stain, sealer)

- 1 – 1×2 at 8′

- 1 – 1×3 at 4′

- 1 – 1×3 at 6′

- 1 – 4′x4′ sheet of 1/4″ plywood

- 1 – 4′x4′ sheet of 1/2″ plywood

- 3 sheets of 4′x8′ 3/4″ plywood

- 8 – 3/4″ square dowels at 4′ or 16 – 3/4″ square dowels at 3′

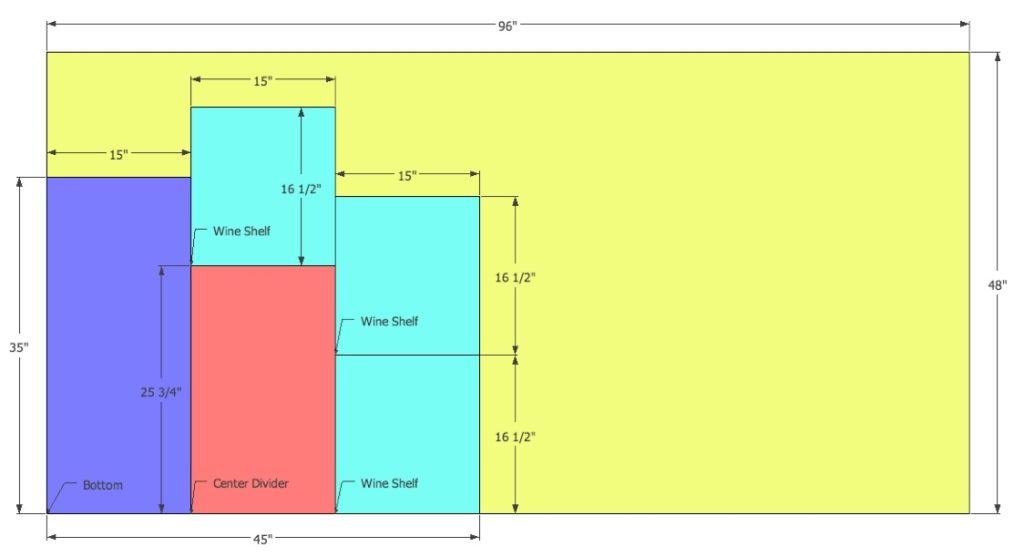

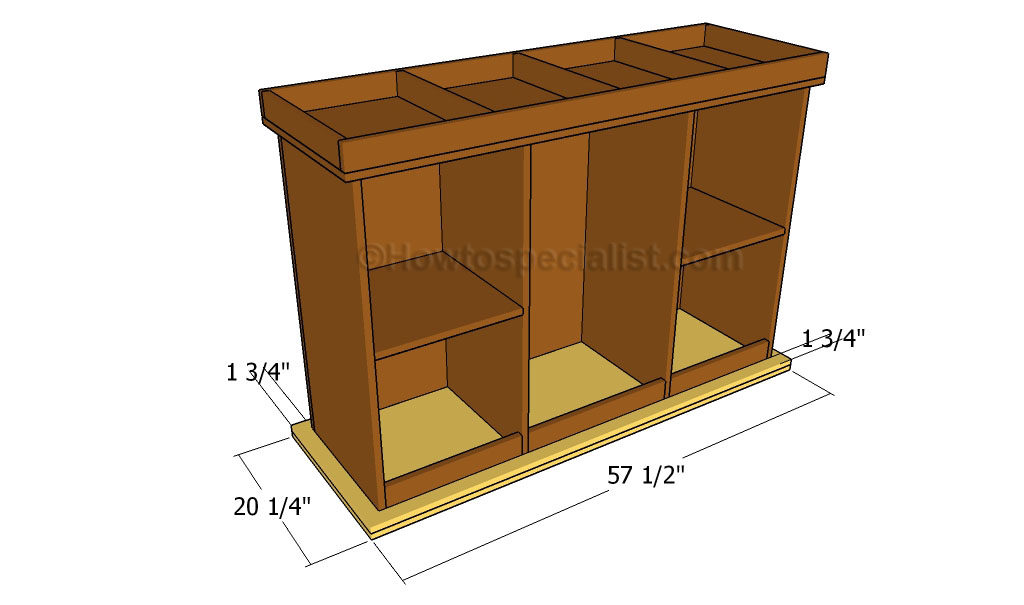

- 2 – 3/4″ plywood at 20-1/4″ x 42-1/4″ – Sides

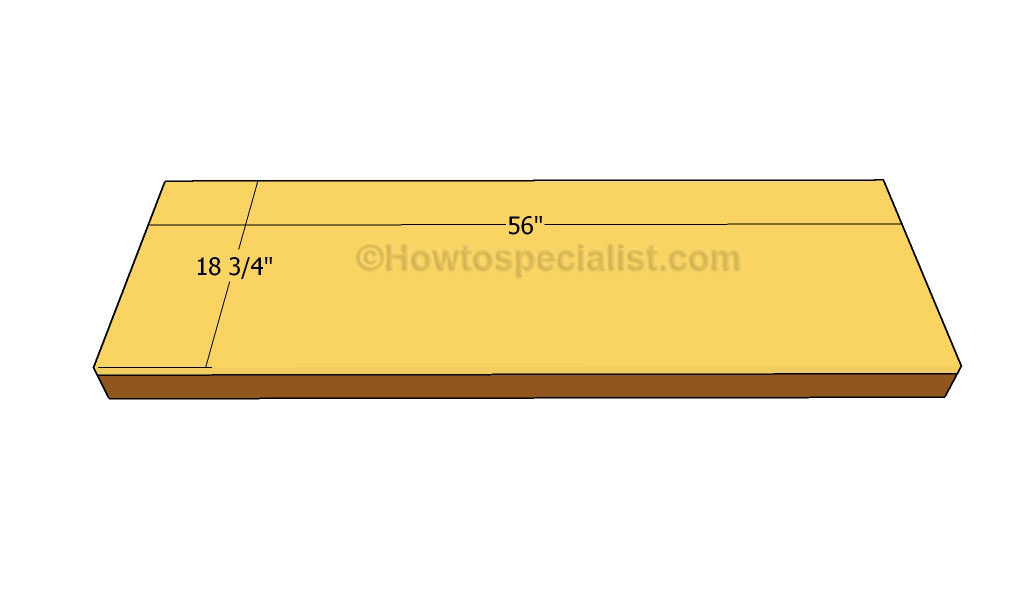

- 1 – 3/4″ plywood at 20-1/4″ x 40-1/2″ – Bottom

- 2 – 3/4″ plywood at 3-1/4″ x 40-1/2″ – Kick Plates

- 1 – 3/4″ plywood at 38-1/4″ x 40-1/2″ – Back

- 2 – 3/4″ plywood at 19-1/2″ x 38-1/4″ – Dividers

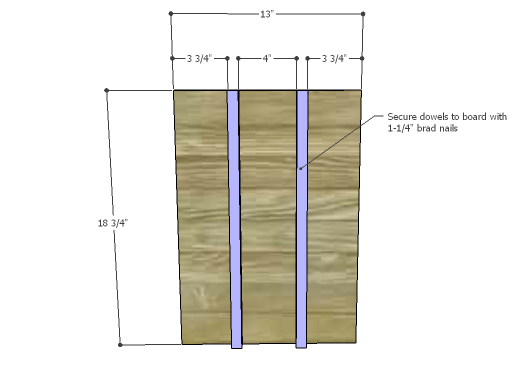

- 16 – 3/4″ square dowels at 18-3/4″ – Wine Bottle Stops

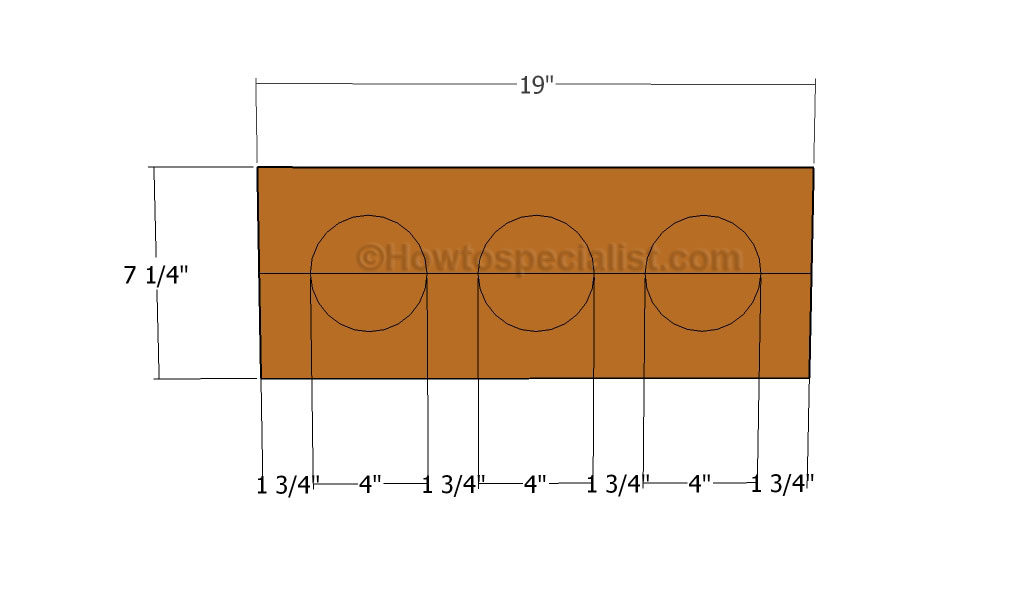

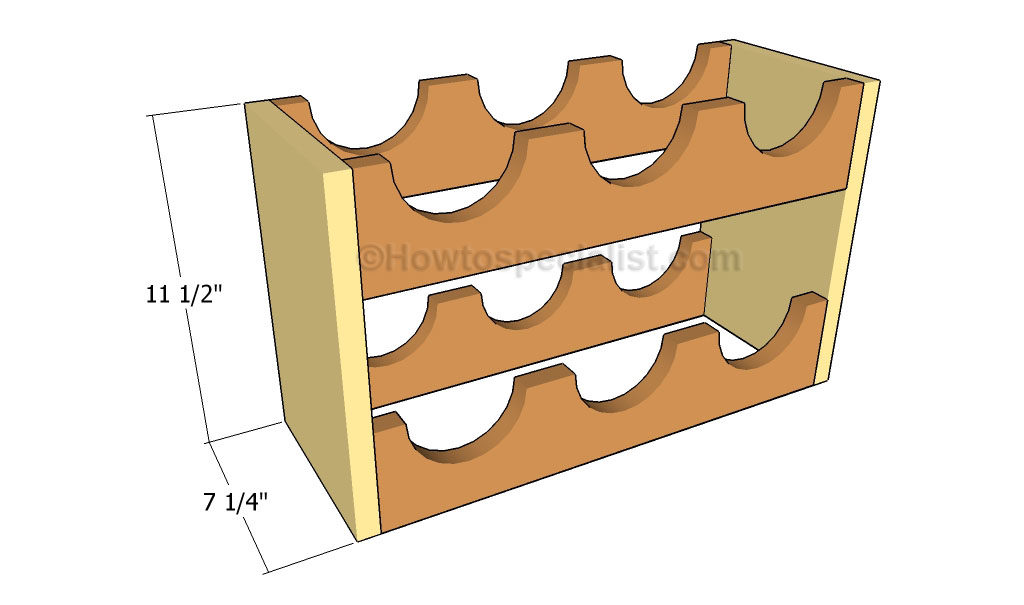

- 6 – 3/4″ plywood at 13″ x 18-3/4″ – Shelves

- 1 – 3/4″ plywood at 19-1/4″ x 40″ – Top Panel

- 2 – 1×2 at 19-1/4″ – Top Side Trim

- 1 – 1×2 at 43″ – Top Front Trim

- 2 – 3/4″ plywood at 12″ x 37-1/2″ – Drawer Front & Back

- 3 – 3/4″ plywood at 12″ x 16-1/2″ – Drawer Shelf Bottom

- 6 – 1×3 at 16-1/2″ – Drawer Sides

- 3 – 1/2″ plywood at 12-3/4″ x 37-15/16″ – Door & Drawer Base

- 15 – 1/4″ plywood at 7-3/8″ x 12-3/4″ – False Drawer Fronts

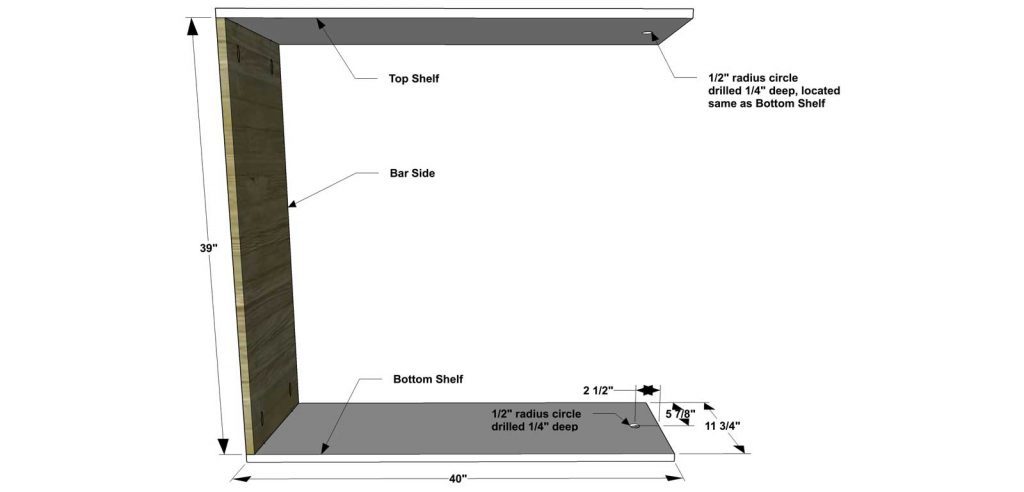

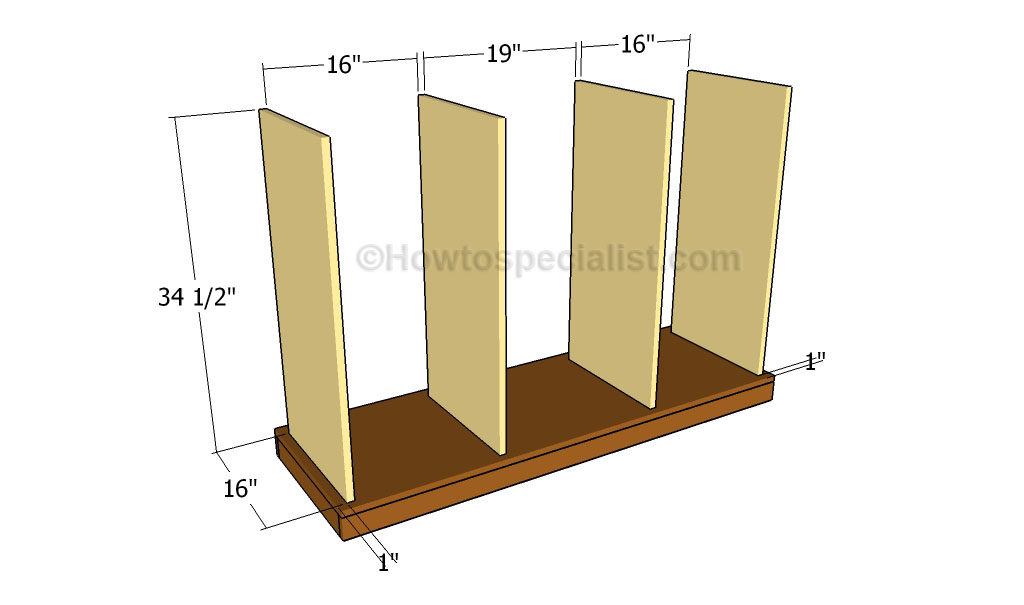

Cut the pieces for the sides and the bottom. With the pocket hole jig set for 3/4″ material, drill pocket holes in each end of the bottom. Position the bottom 3-1/4″ up from the bottom edge of the sides securing in place using glue and 1-1/4″ pocket hole screws.

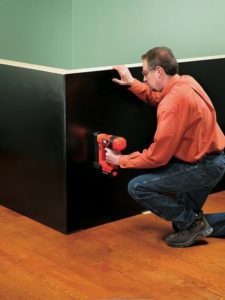

Cut the pieces for the kick plates and drill pocket holes in each end. Secure to the sides under the bottom using glue and 1-1/4″ pocket hole screws. The front kick plate will be positioned 3/4″ back from the front edge of the sides while the back kick plate will be flush with the sides. Add a few 1-1/4″ brad nails through the bottom into the kick plates.

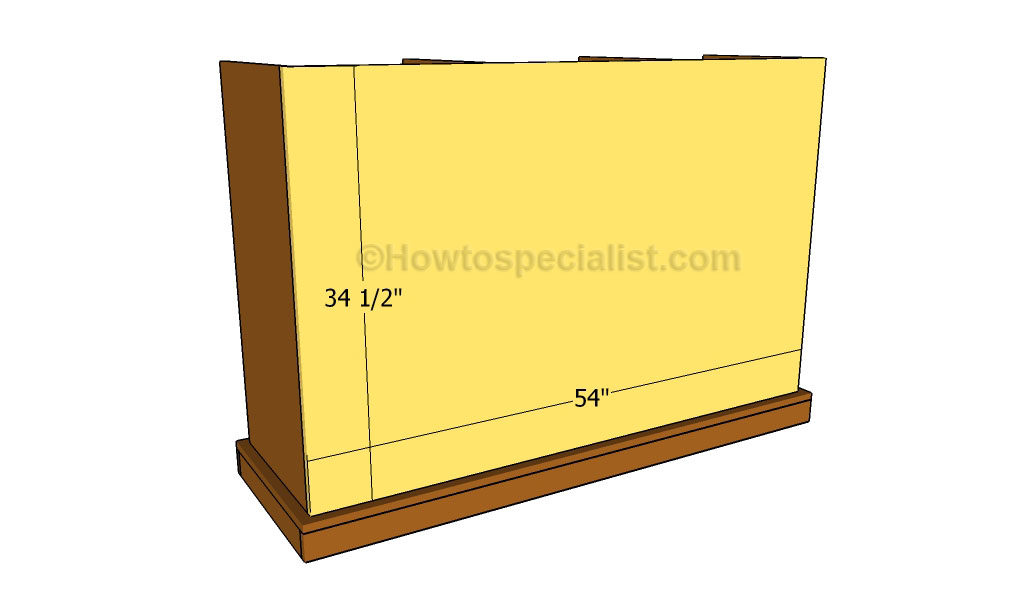

Cut the piece for the back and drill pocket holes in the side and bottom edges. Secure to the sides and bottom using glue and 1-1/4″ pocket hole screws.

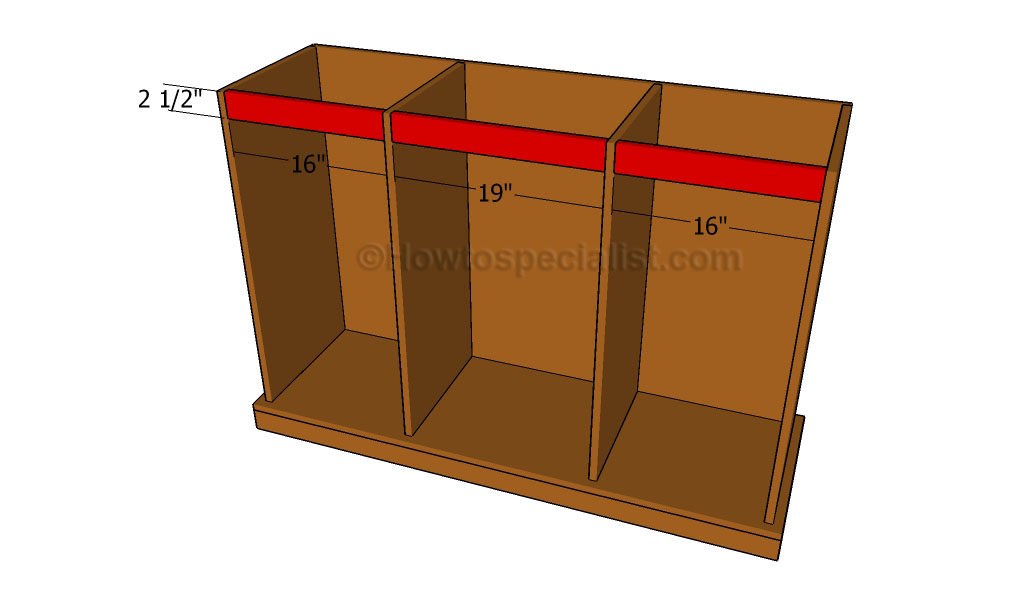

Cut the pieces for the dividers. Drill pocket holes in the back and bottom edges, treating the pieces as if they are a left and a right (this way the pocket holes will be hidden in the center drawer area).

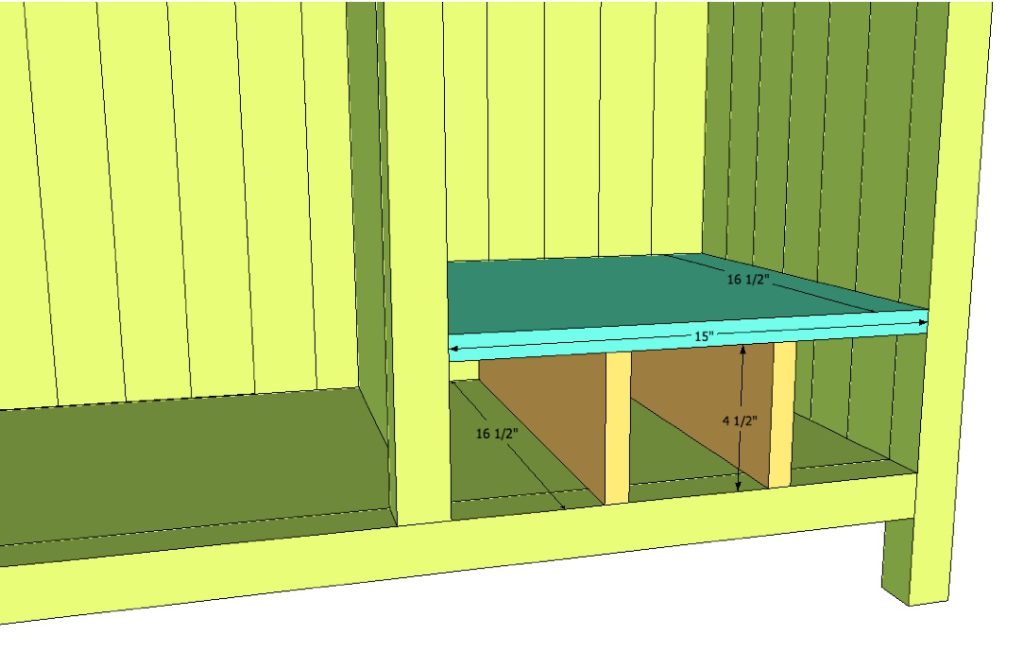

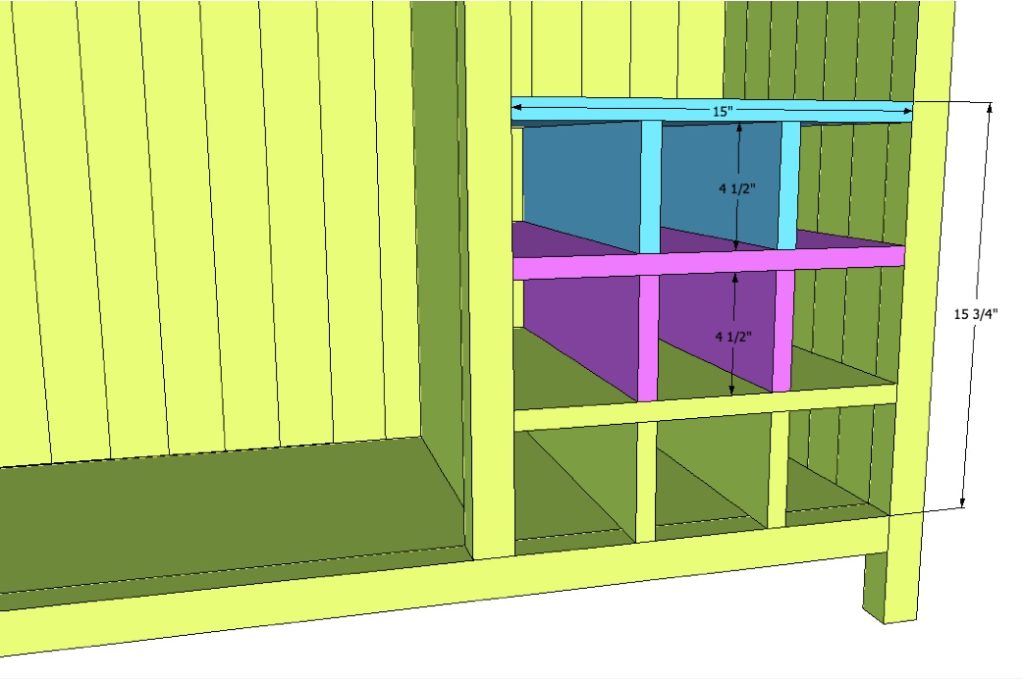

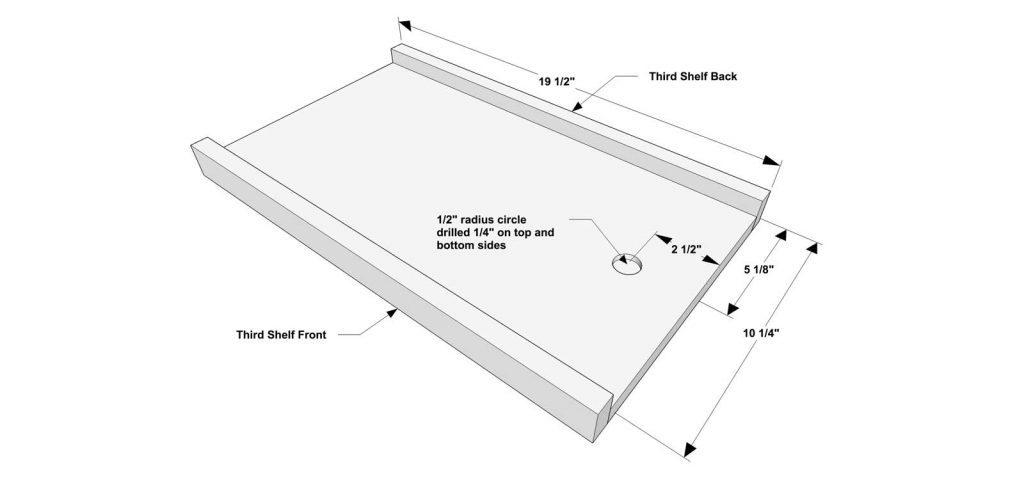

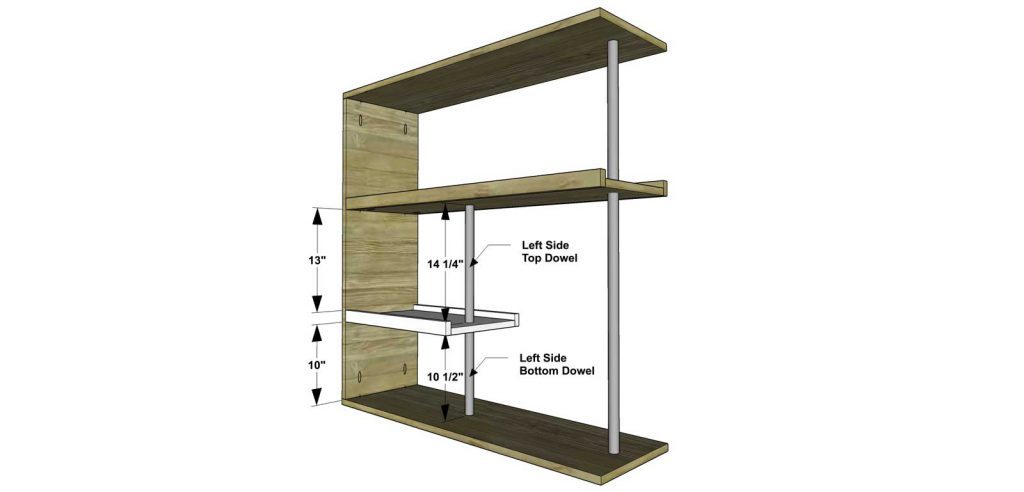

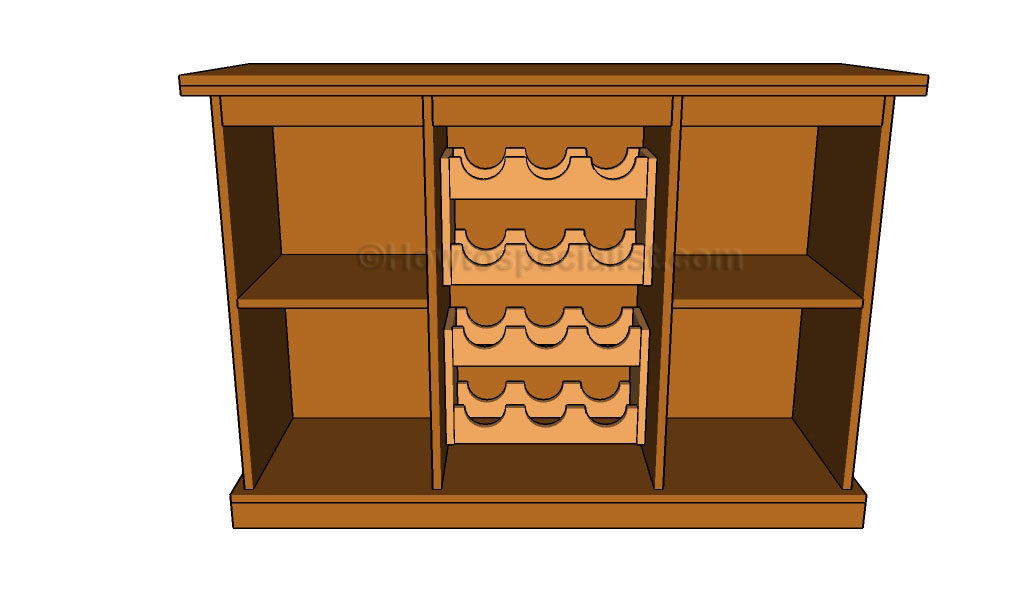

Cut the pieces for the wine bottle stops and the shelves. Attach two stops the bottom of each outer cubby as shown, locating them 3/4″ back from the front edge of the bottom. Secure the stops in place using glue and 1-1/4″ brad nails.

Drill pocket holes in the side and back edges of the shelves. Attach the remaining stops to the top of the shelves as shown using glue and 1-1/4″ brad nails. Position the shelves in the outer side cubbies as shown securing in place with glue and 1-1/4″ brad nails.

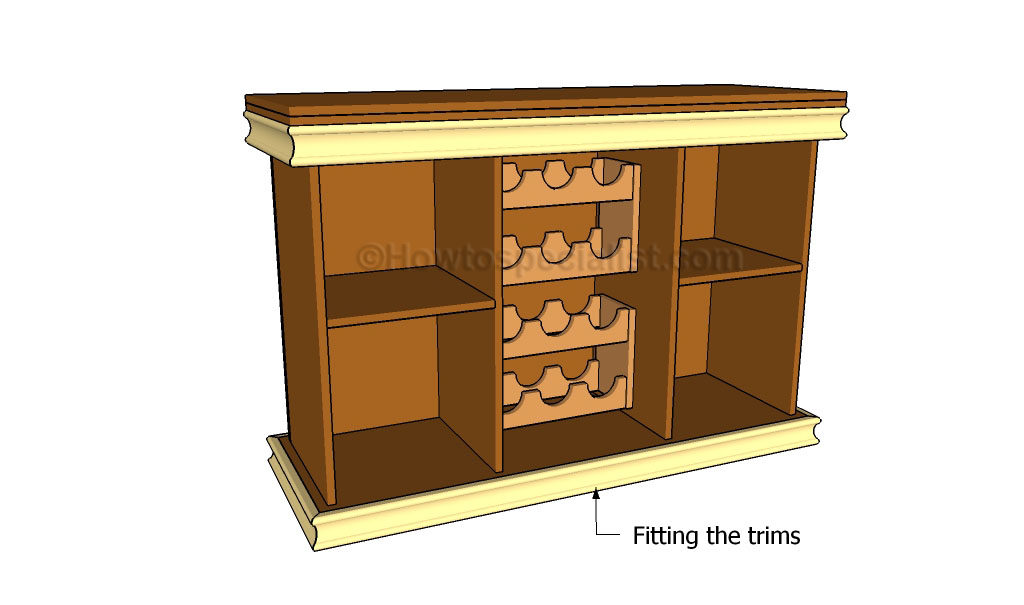

Cut the piece for the top and the top trim. Drill pocket holes in the side and front edges of the panel as well as one end of the side trim. Attach the side trim to the panel first, using glue and 1-1/4″ pocket hole screws. Attach the front trim piece using glue and 1-1/4″ pocket hole screws. Use a router and a decorative bit to cut a fancy edge on the top!

Position the top so that the back edge is flush and the sides and front overhang by 1/2″. Secure the top to the cabinet using glue and 1-1/4″ brad nails.

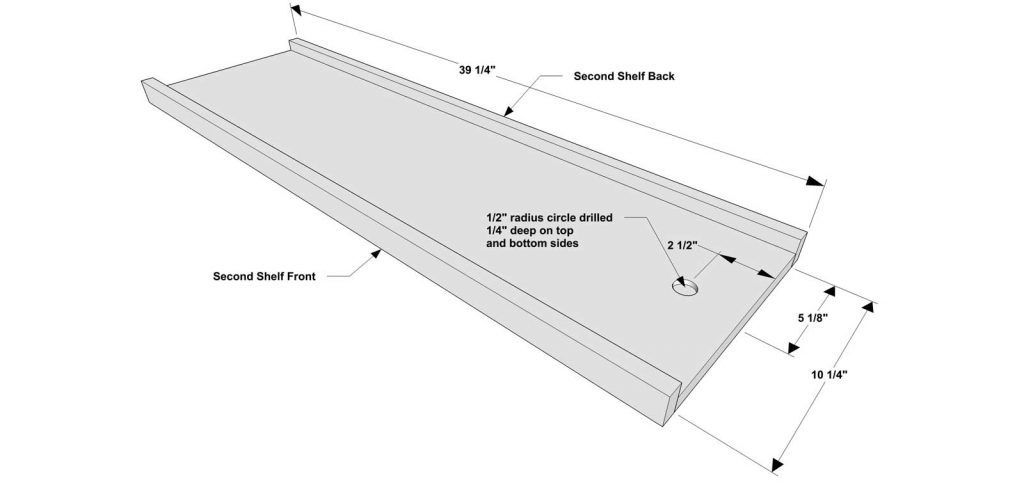

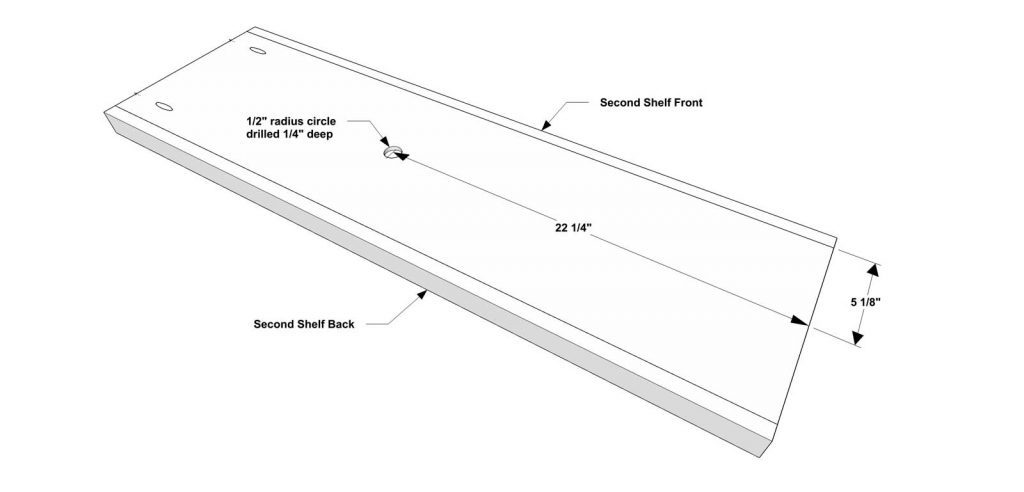

Cut the pieces for the center drawer. This drawer is similar to a traditional drawer but has three shelf compartments. Drill pocket holes in the narrower edges of each bottom piece. Secure the bottom pieces to the front and back pieces as shown using glue and 1-1/4″ pocket hole screws.

Drill pocket holes in each end of the side pieces. Position the side pieces over each bottom piece, securing in place with glue and 1-1/4″ pocket hole screws.

Mark the position for the drawer slides on the dividers – the drawer will sit 1/8″ above the bottom. Install the cabinet side pieces of the drawer slides on the dividers locating the slides 3/4″ back from the front edge, then install the drawer side pieces of the slides on the sides of the drawer. Test fit the drawer and make any necessary to the slides.

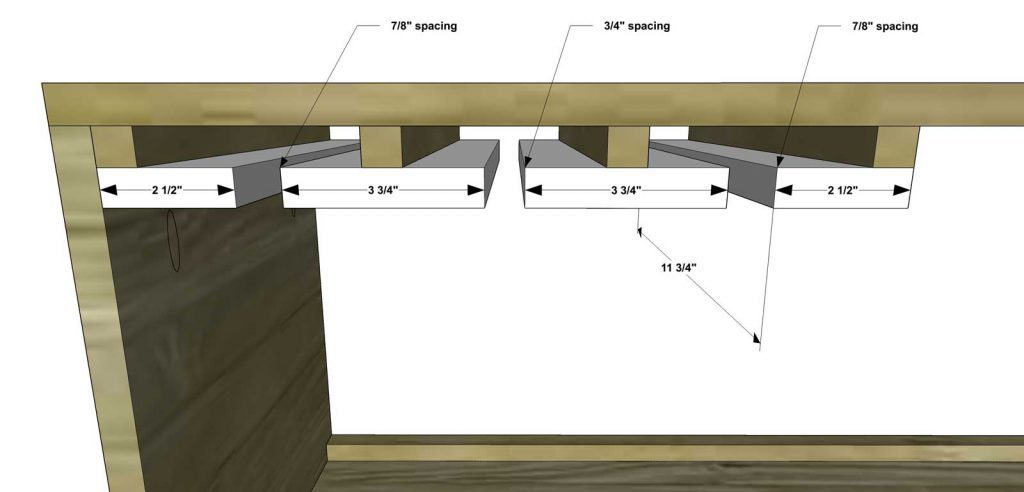

Cut the pieces for the door/drawer front bases, then cut the pieces for the false drawer fronts. Draw placement lines on the base for the false fronts. The top false front will be located approximately 1/16″ down from the top of the base. The remaining false fronts will be spaced 1/4″ apart. Secure the false fronts using glue and 5/8″ brad nails. drill holes in each false front, all the way through the base, for the cabinet pulls.

Shim the drawer front assembly in the center cubby over the drawer. There will be a 1/8″ gap around all sides. Drive screws through the holes drilled for the cabinet pulls into the drawer. Open the drawer, and secure the drawer front from the inside with countersunk 1-1/4″ screws. Finish drilling the holes through the drawer for the cabinet pulls, then install the pulls.

Install the hinges on the doors, then install the doors in the cabinet. There will be a 1/8″ gap around all sides of the doors in the openings. Install the pulls.

Finish as desired.

The original plan can be found at http://designsbystudioc.com