Bar – Corner

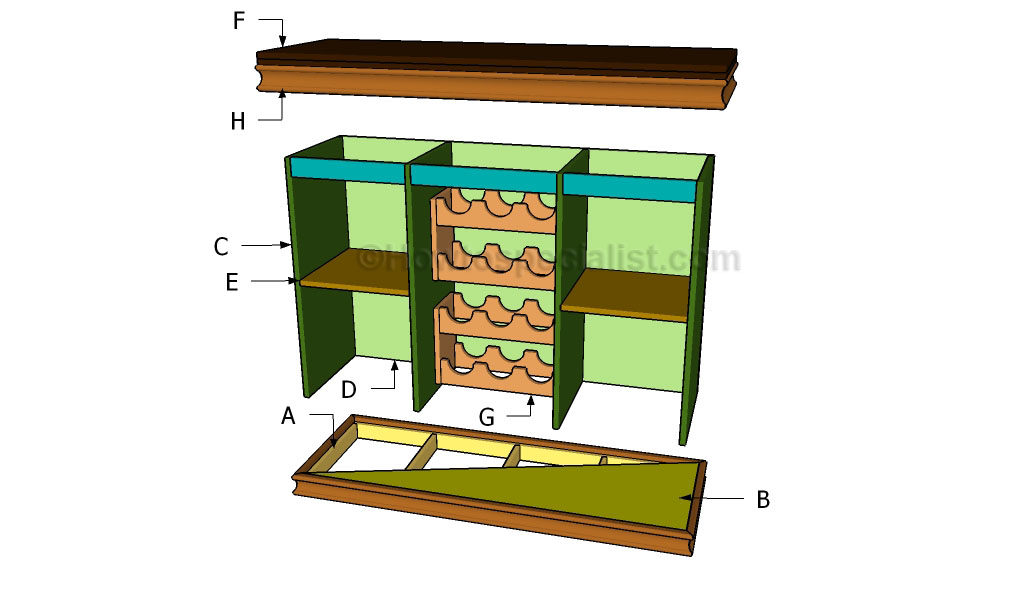

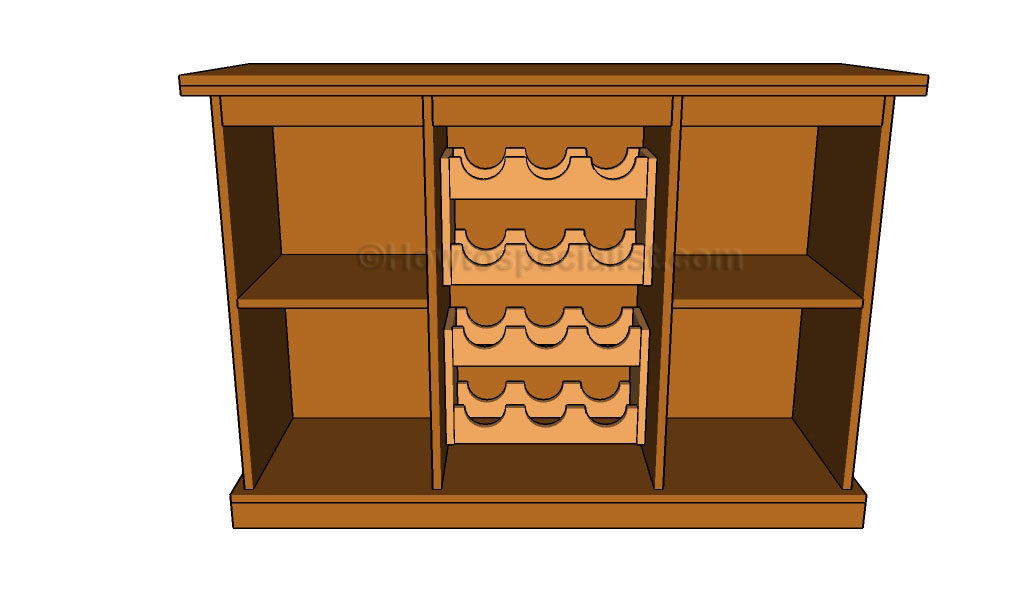

Owning your own in-house bar makes a statement about you. The bar shown here is sleekly styled and smartly laid out for the efficient barkeeper. A small refrigerator gives you access to cold drinks and ice while convenient cabinets create excellent storage spots for party favors. While this is a “dry bar” (no plumbing), the design could be modified in any number of ways to add running water if you wish. All you need to get the party started is a GFCI electrical outlet and the proper floor space.

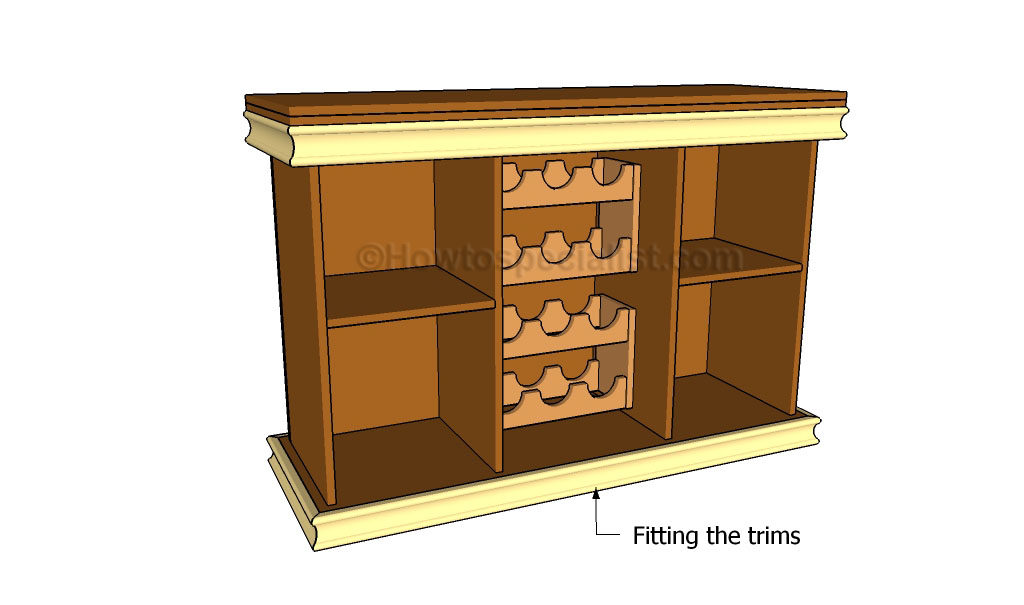

This compact corner bar design features glossy black MDF aprons with decorative cherry appliqués forming a horizontal grid pattern on the aprons. A cherry plywood bar top sits atop a 2 × 6 L-shaped knee-wall, harboring some practical amenities on the bartender side. A flip-up lift gate in the bar top on one end provides pass-through access and can even function as a wait station if you want to get really fancy in your hosting. The key components— base cabinets, a laminate counter top, the fridge, and the wood for a sleek Asian inspired style trim-out—set the stage for your next gathering. Let’s party!

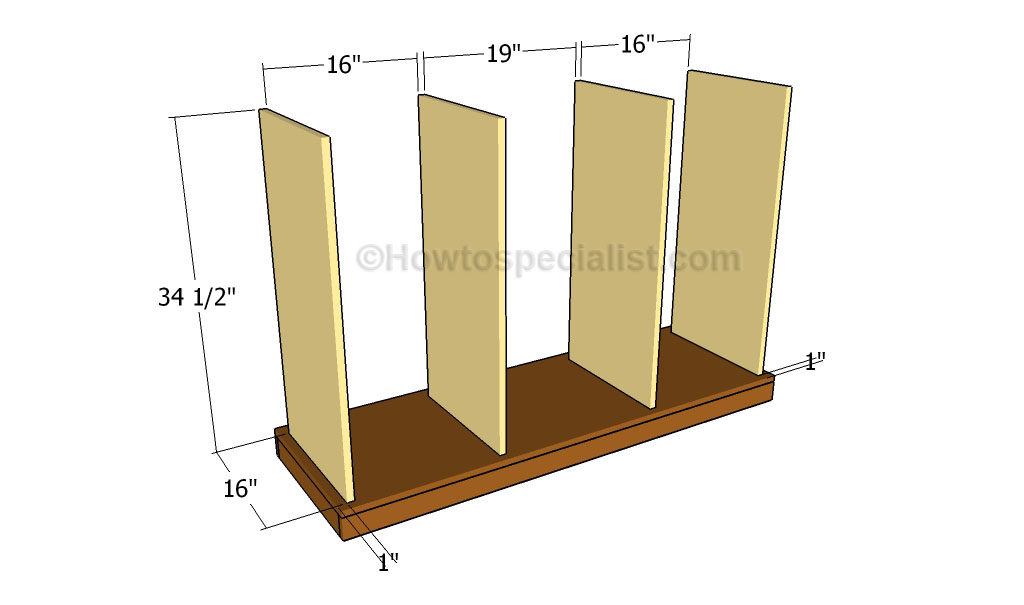

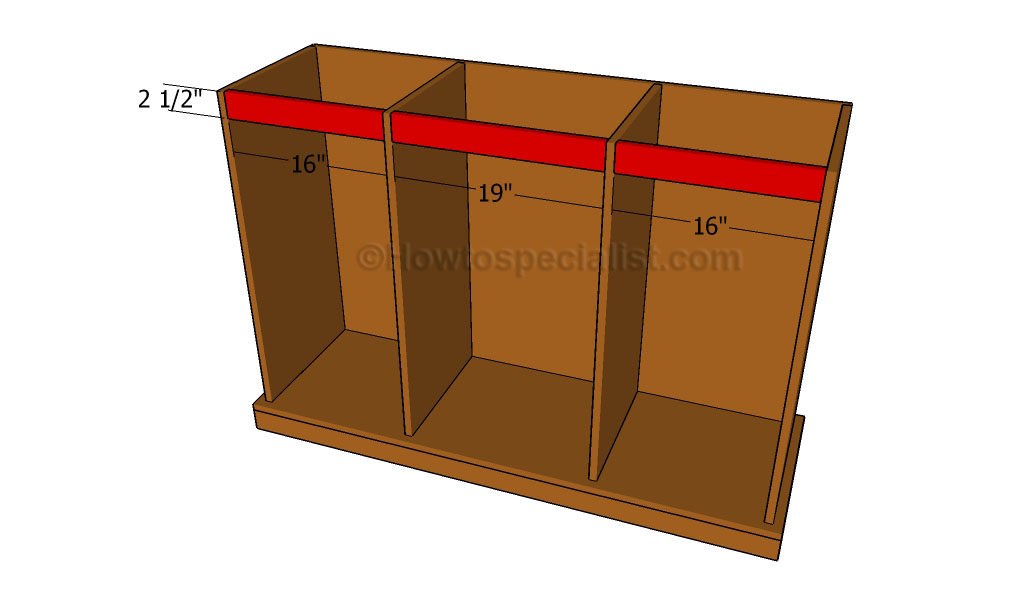

Anchor the sill plates for the knee-walls to the floor so they form a right angle at the corner where they meet. Use 16d common nails or screws and panel adhesive for a wood floor; use a powder-actuated nailer on a concrete floor.

Use panel adhesive and deck screws to attach the end knee-wall stud to the back wall, attaching at a stud location. If there’s no stud, open the wall and insert a horizontal nailer between the nearest studs.

Use 16d common nails to toe-nail the corner studs to the sill plates. Use a level to make sure the studs are vertical.

Complete the framing for the L-shaped knee-wall section. For extra strength, drive a few 3″ deck screws through the studs where they meet at the corner.

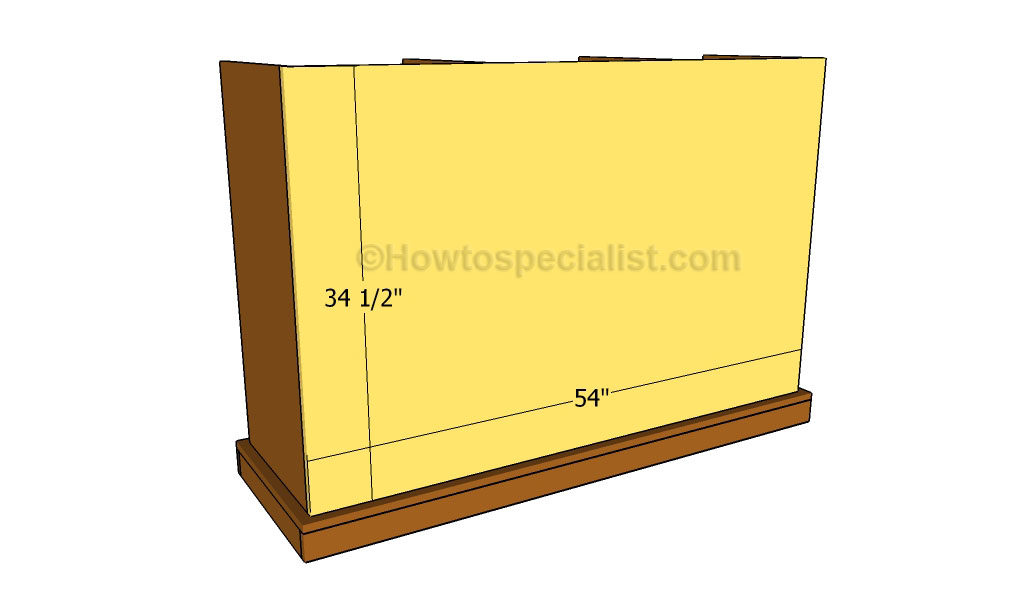

Rip two sheets of 1/2″ MDF to 40 1/2″ wide and trim them to length to make the bar front panels. Sand edges to remove any saw marks. For the smoothest possible finish, spray the front apron panels with an HVLP sprayer. Apply the paint or lacquer over primer, in thin coats.

Prepare at least 80 lineal feet of 3/4 × 11/2″ hardwood stock to trim out the aprons and edges of the bar-top.

For efficiency, apply a protective finish to the cherry apron trim stock. Dab some finish on the cut ends after you cut each trim piece to length.

Apply panel adhesive to the knee-wall studs to strengthen the bond with the black aprons. Slip a 1/4-thick spacer beneath each apron to create a gap between the panel and the floor.

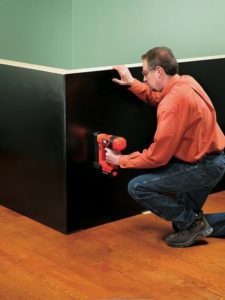

Attach the aprons with a pneumatic nailer and 2 1/2″ Finish Nails Nail the apron panels to the wall studs at 8″ to 12″ intervals.

Attach cement board strips to the edges of the knee-wall framing members as a backer for the backsplash area.

Install the inside wall covering before you cap the wall. We used inexpensive 4 x 4″ ceramic wall tile set into a layer of thin-set adhesive that’s troweled onto the cement board.

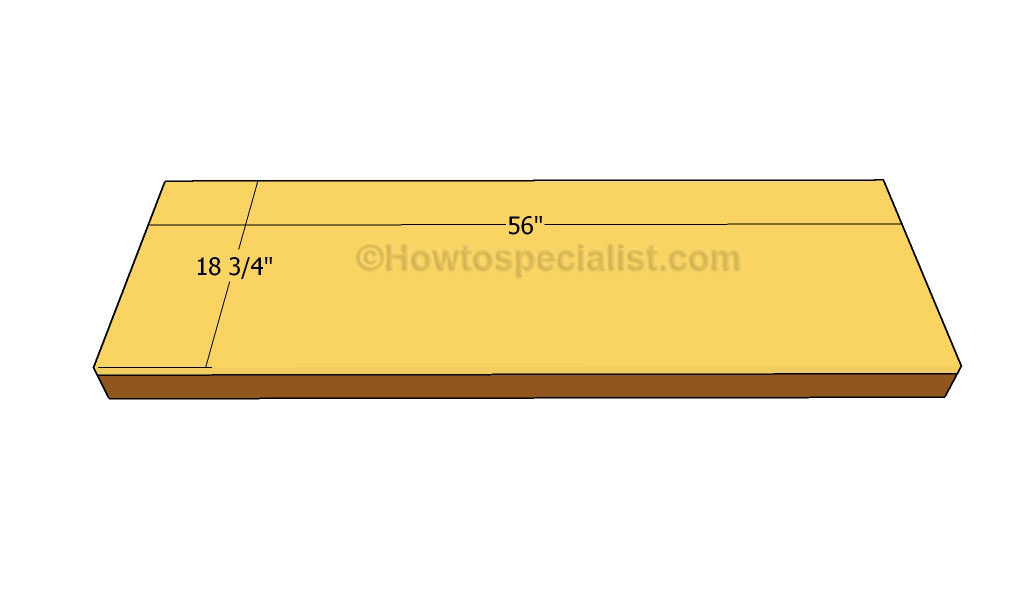

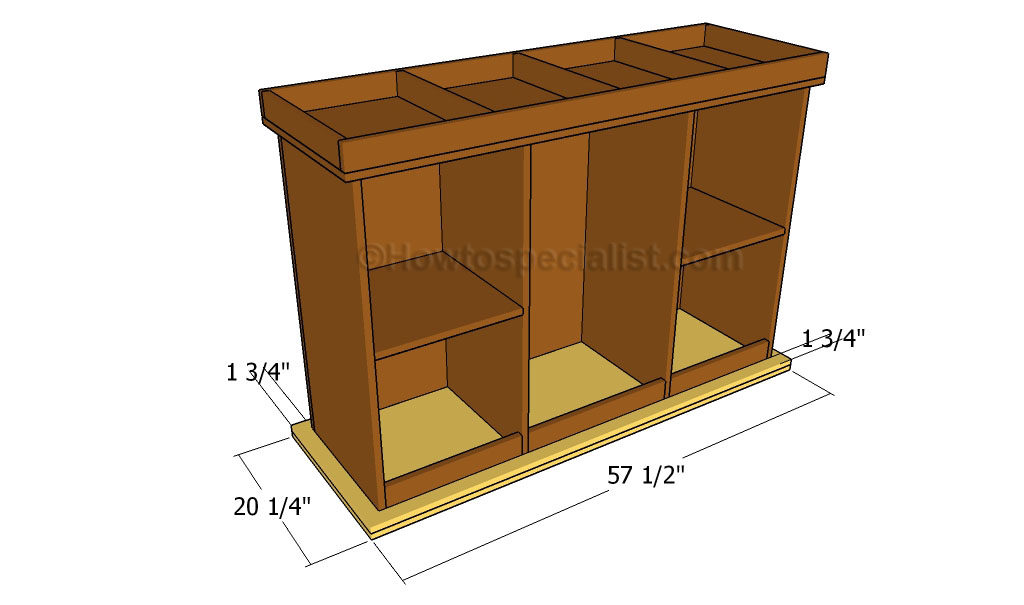

Bond the particleboard sub-base directly to the top plates of the knee-walls, taking care to achieve even overhangs of 6″ in front and 4″ on the bartender side of the walls.

Drive plenty of 2″ deck screws to secure the sub-base to the walls. The screw heads must be sunk beneath the wood surface.

Make 45-degree miter cuts in the bartop top layer using a circular saw and cutting guide.

Laminate the top layer of cherry plywood to the sub-base with panel adhesives and 1 1/4″ screws driven up through the sub-base.

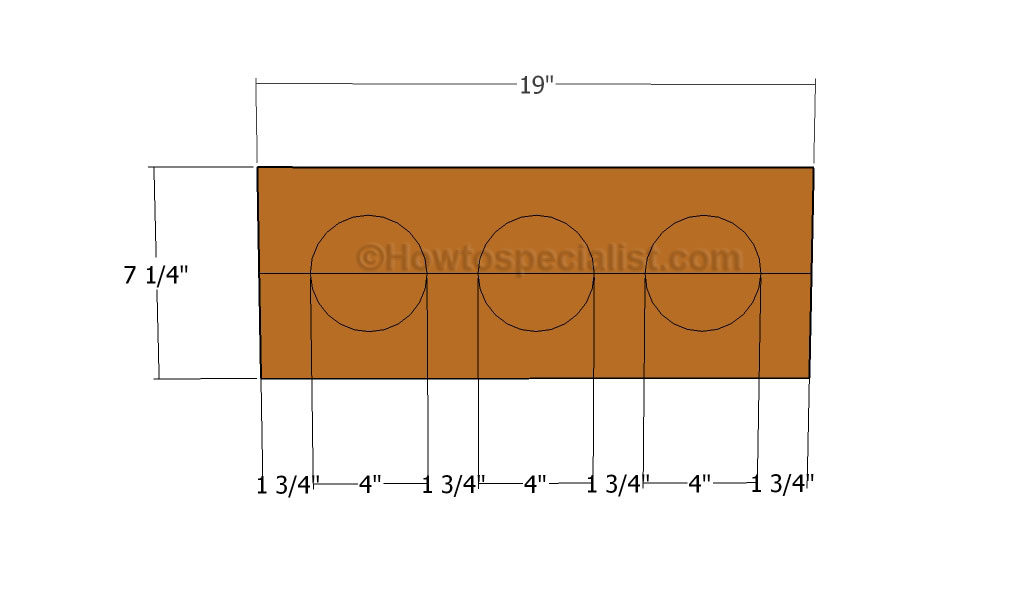

Cut a round-over profile in one edge of the cherry edging stock and then cut the parts to length and attach them to the edges of the bartop with nails and glue.

Square-cut a piece of 1 × 2 edging to fit exactly between the ends of the round-over edging, and nail and glue it into place.

Nail the cherry end panel to the wall end to conceal the stud wall and the edges of the wall coverings and trim.

Attach a 1 × 2 stop block for the lift gate to the wall directly above the wall-mounted end panel.

Attach the piano hinge to the lift gate section of the countertop first, then attach the other leaf to the countertop.

Attach the lift gate to the countertop and test to make sure it operates smoothly and correctly.

Add the decorative cherry strips in a ladder grid pattern, using an air nailer. Start with the vertical strips, then cut the horizontals to fit.

Attach a countertop to the base cabinets to create an easy-to-clean work surface for the bartender.

Slide in a refrigerator, or any appliance you choose.

The original plan can be found at http://www.freewoodworkingplan.com