Several months ago I was watching an episode of “Fixer Upper” and caught glimpse of a custom-built shiplap headboard. Since then, I haven’t been able to get the idea out of my head. I don’t have a cool old house with shiplap walls that I can tear down, so I came up with my own solution for a DIY headboard made of faux shiplap— all using materials all found at my local Home Depot store.

Materials:

- (1) 8 ft.- 2 x 12

- (3) 8 ft.- 2 x 4

- (1) 4 x 4 ft. x 3/8 in. sheet of plywood or MDF

- (1) Timeline Wood Distress—ed Grey Wood Panels – 6 pack

- (3) 21 in. Galvanized metal strap

- (3) 5 in. Galvanized tie plate

- 2½ in. Pocket hole screws

- 5/8 in. Wood screws

- 7/8 in. Wood screws

With this DIY headboard project, you can create any kind of arch you’d like (radius, elliptical, cathedral, etc.).

You can create the round shape using a pencil on a string, compass, or even tracing a large round object. Whatever arch shape you choose, make sure the ends are parallel.

Step 1: Create A Template

First, I vertically taped together sheets of 8½ x 11 in. paper. Then I cut the resulting strip of paper to 38 in. in length (the width of the eventual headboard). I folded the sheet in half and sketch half of an arch, 3½ in. wide. I then cut out my half-arch, and opened the paper to reveal the full shape.

Step 2: Cut the shape of the template

I aligned the outside edge perpendicular to the long sides of my 2 x 12. Using a pencil, I traced the arched shape onto the wood.

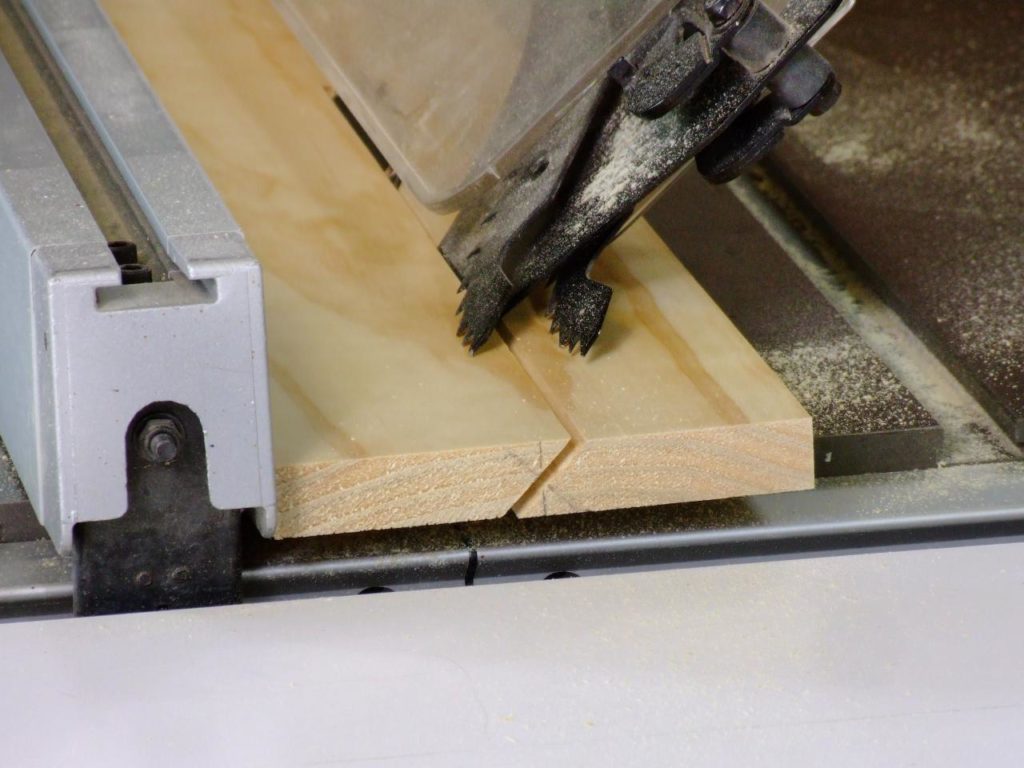

Next, I cut along the line using a jig saw with a wood blade.

Step 3: Sand the edges of the Arch

I took my time to sand the cut edges really well, helping to remove any blade marks and to smooth the arch’s shape.

Step 4: Drill the pocket holes

Using a circular saw, I cut two 2 x 4’s, 52 in. in length and one 38 in. in length. I drilled two, 1½-in.-deep pocket holes on either end of the shorter board, and on both ends of the arch.

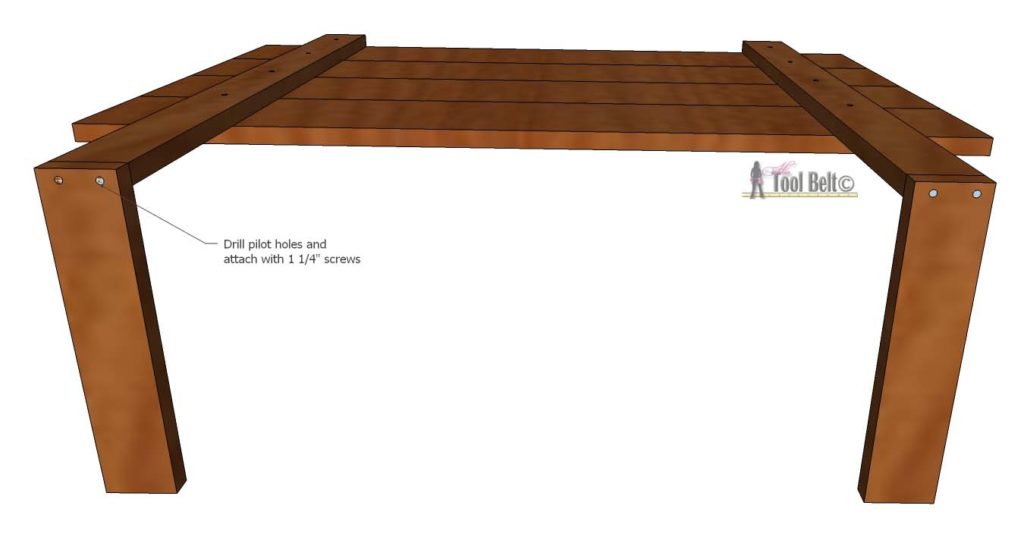

Step 5: Attach sides to the arch

Next, I laid my 52-in. 2 x 4’s on the ground, face down. I aligned the end of the arch with the top of each 2 x 4 and connected the two with wood glue and 2½ in. pocket hole screws.

Step 6: Attach bracing board

I measured 20 in. from the bottom of each leg and made a pencil mark. I placed the 38 in. board perpendicular between the legs, face down, and lined up the bottom of the board with both pencil marks. I connected the board to the legs with more wood glue and pocket hole screws.

Step 7: Paint the plywood

I knew I would be able to see a small amount of plywood between the wood slats of the faux shiplap, so I needed to make sure the color of the plywood matched the pre-finished slats. I used a roller to paint one side of the plywood a medium grey.

Step 8: Attach the faux shiplap slats

Once the paint had dried for several hours, I started attaching the faux shiplap slats.

I started on one edge of the plywood and lined up the slats parallel to each other. I used a couple pieces of scrap wood ¼ in. thick as spacers between each slat. Quarter inch tile spacers would work well, too.

To give my plywood more rigidity, I ran the boards in the opposite direction of the wood grain on the plywood. I applied a healthy “squiggle” of construction adhesive to the back of each slat and pressed it firmly into place.

I had a few edges that popped up and didn’t want to stay put. So, I placed a couple dumbbells on those areas to hold them down and let the adhesive dry fully.

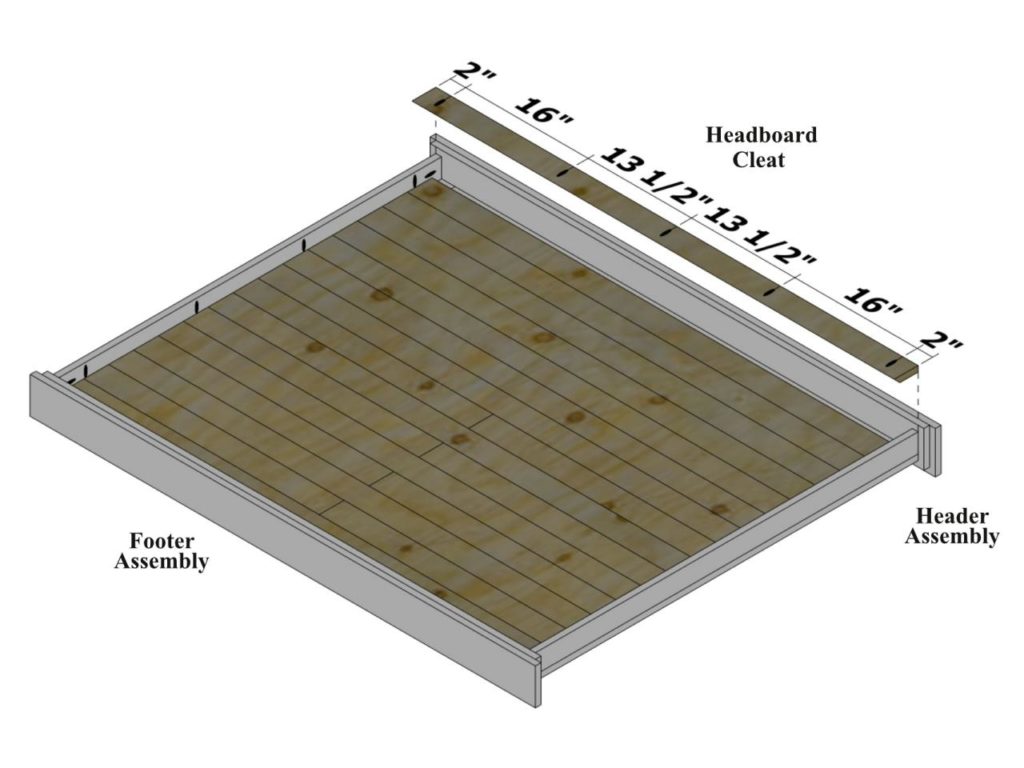

Step 9: Lay the headboard frame on the faux shiplap strips

After the construction adhesive had several hours to dry, I laid the headboard frame, face up, on top of the panel. I made sure that the slats ran horizontally.

Step 10: Trace the inside of the frame

With a pencil, I traced along the inside of the frame. If you are comfortable using a router, skip to Step 11b. If not, as smoothly as possible, cut out the traced shape from the panel using a jig saw.

Step 11a: Secure the panel to the headboard arch

Flip the frame face down. Lay the panel, face down, in the center. Use scrap wood to raise the panel until the back of the plywood is flush with the back of the frame. Center your three 21 in. metal straps along the seams and drive 5/8 in. screws, securing the frame and plywood panel together. Screw in your three 5 in. tie plates spaced evenly over the arch to secure the plywood panel.

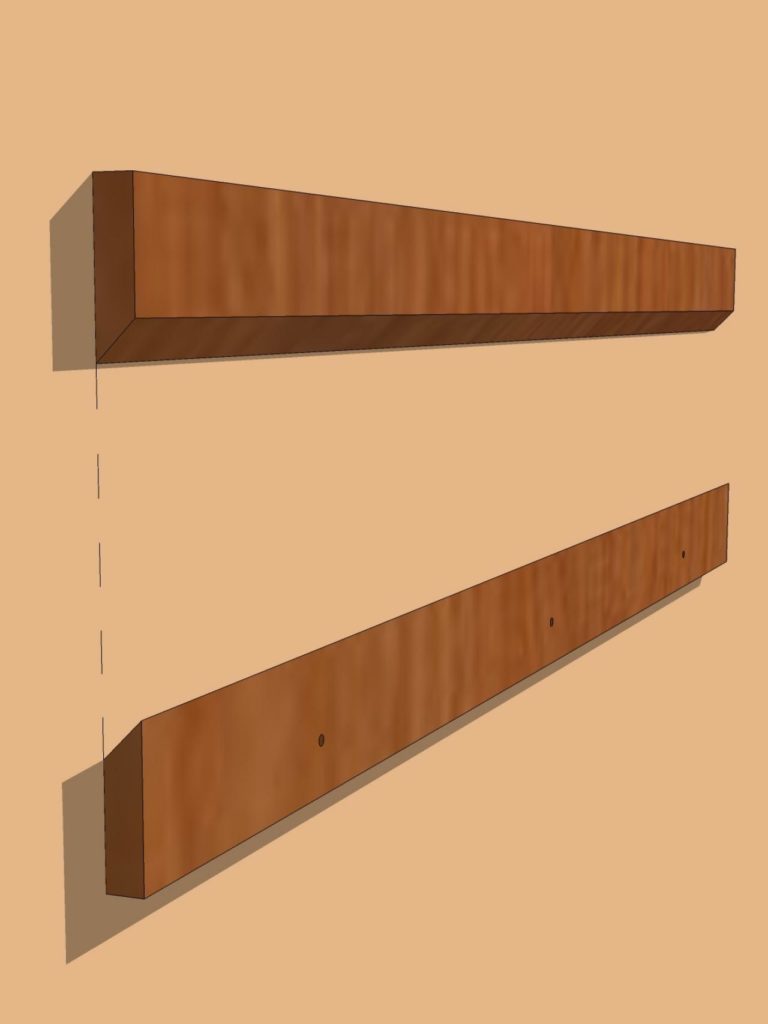

Step 11b: (Router option) Cut a rabbet along edge of headboard arch

I chose to use my router with a ½ in. rabbetting bit and ditched the metal straps all together. Instead of cutting the panel along the traced line, I cut ½ in. outside the traced shape. Then, I ran my router along the inside edge on the back of the frame, cutting a ½ in. wide, ¾ in. deep rabbet. Remember, when removing a large amount of material like this with a router, its best to start shallow, make multiple passes, and gradually cut deeper till you reach your desired depth.

Step 12: Stain and seal the headboard frame

Before attaching the panel, I took time to stain and finish the headboard frame. I was able to match the pre-finished wood slats pretty well by using a water-based grey stain, followed by whitewash of a cream colored acrylic paint. I also sealed the frame with three coats of a clear lacquer in a satin finish, to give the wood extra durability.

Step 13: Attach the faux shiplap to the headboard frame

Once everything was dry, I attached the panel to the frame. I dropped the panel into place and secured it with 7/8 in. wood screws, spaced about every 6 in. apart, along the perimeter of the panel. To avoid splitting, I pre-drilled pilot holes before driving the screws.

The original plan can be found at http://blog.homedepot.com/diy-headboard-faux-shiplap/ target=”_blank” and was created by Pneumatic Addict

[email_link]

[email_link]