Bar Cart

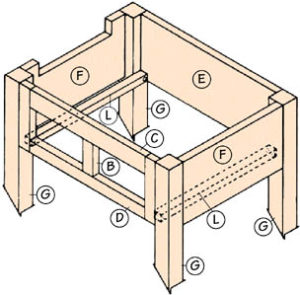

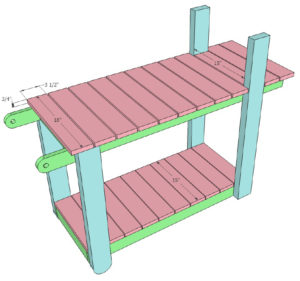

If your usual method of serving beverages at a barbecue involves a Styrofoam cooler and a bag of ice, it’s time to think about an upgrade. This mobile cart is tough enough to withstand sun, rain, and spills of your libation of choice. Two-wheeled construction lets you navigate stone patios or lumpy lawns with ease, and the top tray is removable for serving drinks or munchies. Best of all, the entire thing can be easily taken apart and stored flat—or, better yet, stashed in your trunk for tailgate parties this fall. What better project to celebrate the beginning of grilling season? This Old House senior technical editor Mark Powers shows how to put it together using cedar and outdoor-grade materials.

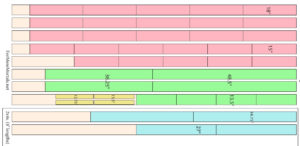

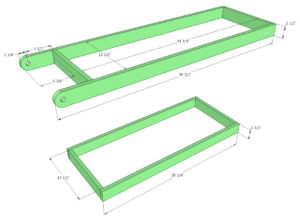

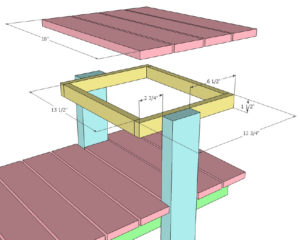

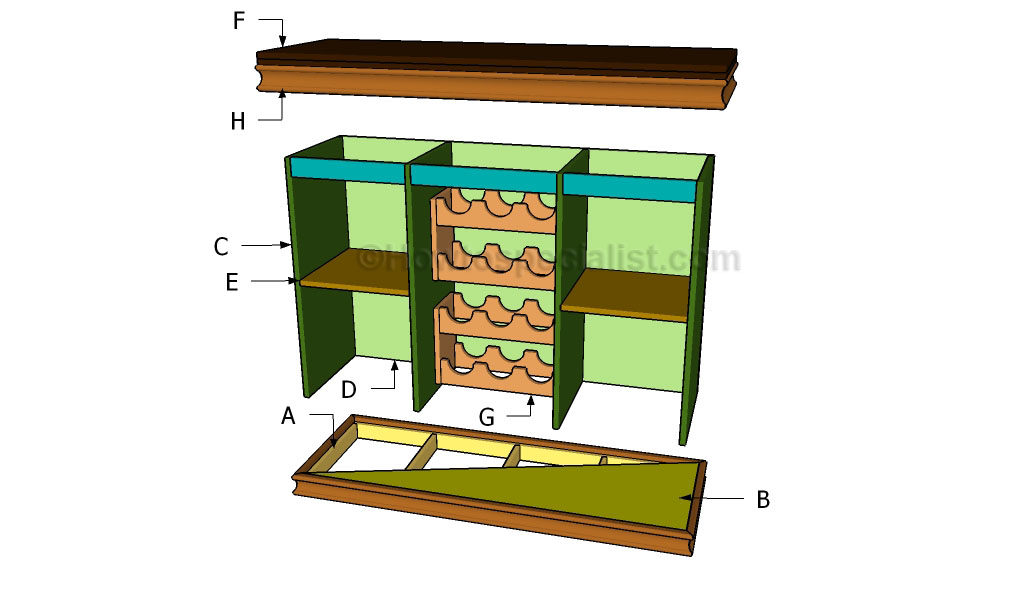

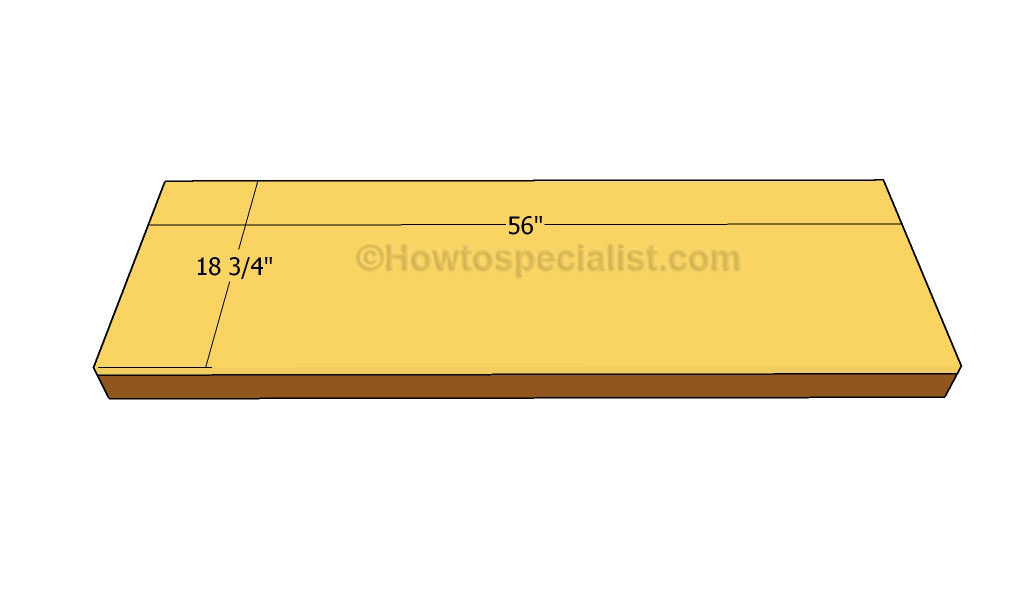

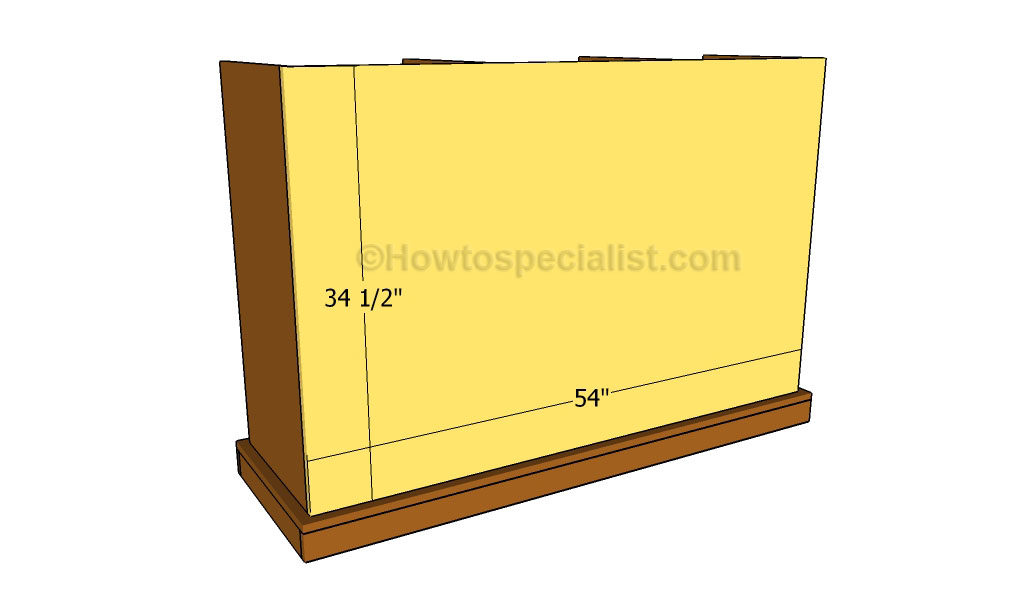

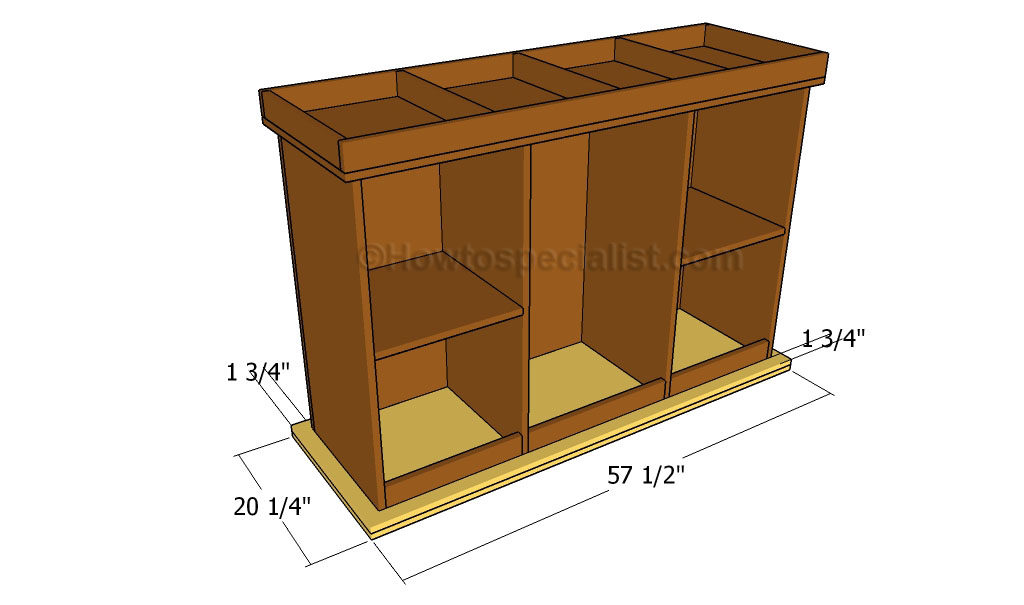

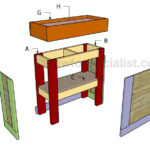

Use a miter saw and a stop block to make cuts of the same length quickly; refer to the illustration for dimensions. For the top tray, cut two 1×4 short sides and two 1×3 long sides. For the bottom tray, cut short and long sides from 1x3s. Cut 19 1×3 bottom boards (nine for the top tray, 10 for the bottom one). Rip a 1×2 in half and cut four ledges to support the bottom boards.

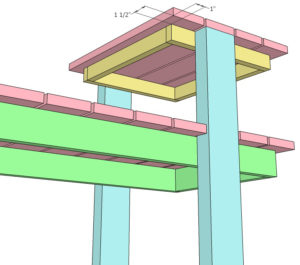

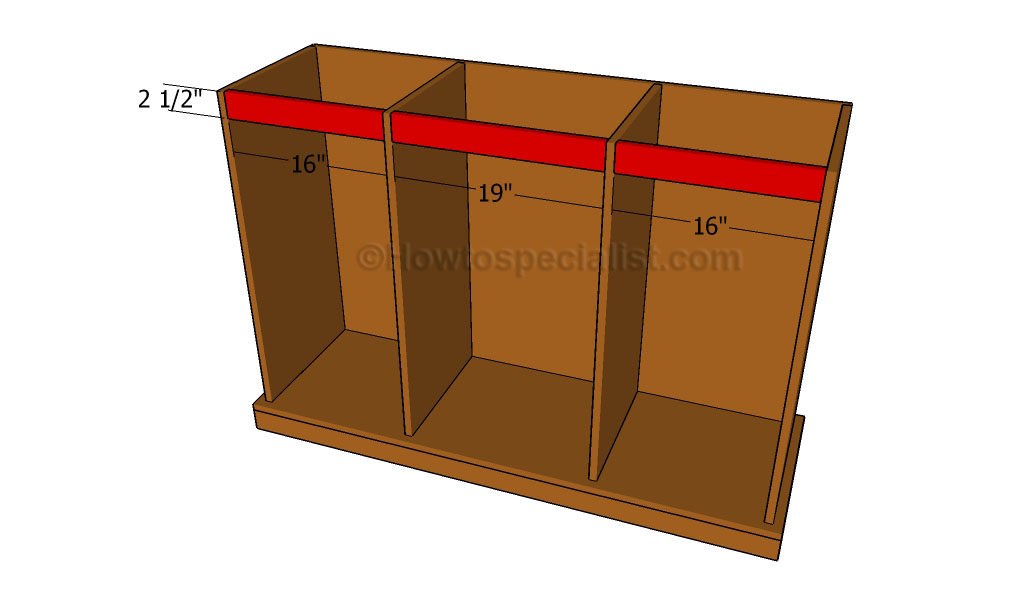

Cut 2x deck pickets to make crosspieces to support the removable top tray. Cut the cart’s handle from a 1-inch hardwood dowel. Cut off the corners of the top tray’s 1×4 short sides so that each edge is 2½ inches tall and even with the height of the long sides. Use a wood file to round over the cuts, then smooth the cut pieces with sandpaper and a block.

Use a paint can to trace a centered arc to make a handle on both 1×4 (short) tray sides. Make sure the cuts are at least ½ inch below the top edge and 1¾ inches above the bottom edge of the 1×4. Use a jigsaw to cut out the handles. Use a file to smooth the cut surfaces.

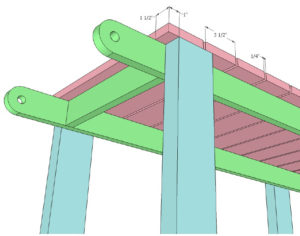

Lay a long side on the flat, and use a 1×3 turned on edge to mark off space at the ends, where the short sides will be attached. Apply wood glue along one edge of the long side between the marks. Press a ledge into the glue, flush with the edge of the side piece. Use the nail gun to drive 1 3⁄8-inch nails a few inches apart through the ledge and into the long side. Repeat for the three remaining long sides.

Apply glue to the cut edge of a short side and the end of a long side. Butt the pieces together to form a corner. Use the nail gun to drive a nail through the top and bottom of the long side and into the edge of the short side. Repeat for all joints for tray frames.

Apply glue to the ledges of the top tray. Lay nine 1×3 boards across the ledges, using a couple of screws as spacers between them to facilitate drainage. Use the nail gun to secure the ends of the boards to the ledges. Repeat for the bottom tray, using 10 boards.

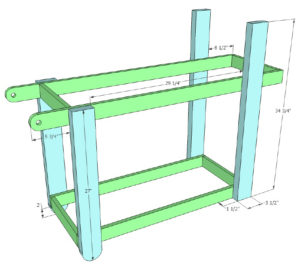

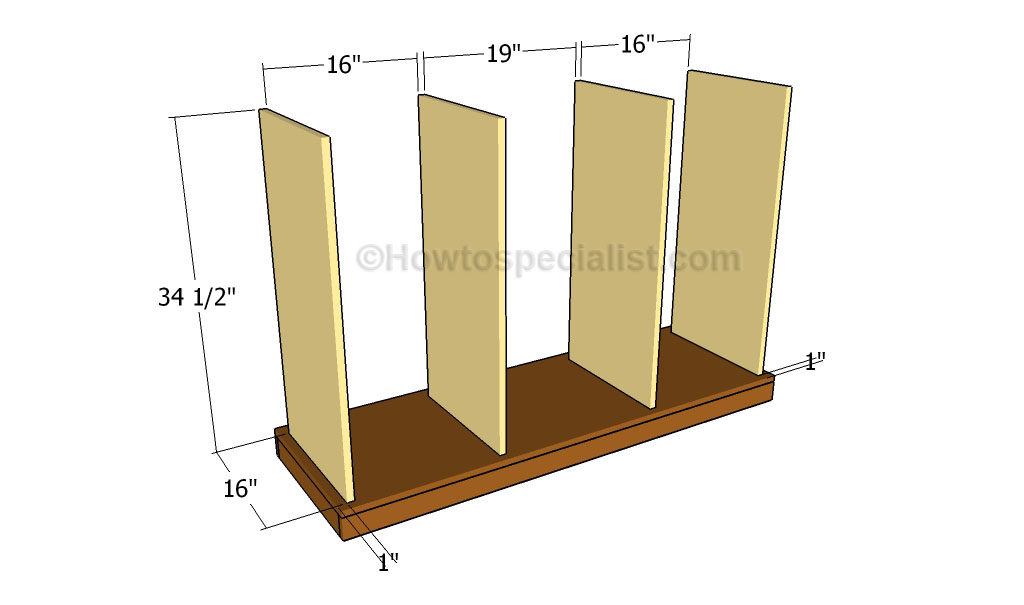

Refer to the illustration for all dimensions. Use a miter saw to make parallel 45-degree cuts on four 1x2s to cut them to size. Cut ¼ inch off the long points at each end. Lay the A legs on the flat and side by side, with the cut-off long points flush at one end, as shown (the short points meet at the other end). Mark each leg’s surface as an “outside face.” Measure and mark hole and notch locations on both legs. Repeat for the B legs, but mark each leg’s surface as an “inside face.”

Turn all the legs on edge. Mark each one at the midpoint of the edge, between the marks, to designate the depth of the notch cuts.

Tip: When marking multiple pieces to be drilled or cut in the same spots, measure off the first one and use a combination square to transfer the marks to other pieces at the same time.

Using a miter saw, make several kerf cuts between the notch marks on the outside faces of the A legs and the inside faces of the B legs. Stop at the midpoint you marked in step 7. Use a chisel to remove the wood.

Using a drill/driver, with bits sized to the holes shown on the illustration, drill holes through the legs, except for holes through the notches. On the outside faces of the A legs, drill countersinks for the cart handle’s screws. Flip the A legs over; on the inside faces, center a 1-inch paddle bit over the countersinks and make ¼-inch recesses for the handle. Smooth cuts with sandpaper.

Fit together the notches on the A and B legs for one side of the cart. Drill a centered ¼-inch hole through both legs at the notched intersection. Slip the post end of a 5⁄8-inch screw post through the notch hole in the B leg. Lay the legs on a work surface, A leg facing up, and slip the screw end of the screw post into the notch hole in the A leg. Begin screwing it into the post by hand, then tighten with a screwdriver. Repeat for the second side of the cart.

Refer to the illustration for hole locations. Measure and mark spots for pilot holes for the bottom tray; make sure they’re ½ inch above the tray’s bottom. Use a 3⁄8-inch bit to drill four holes through the tray’s long sides and ledges.

Tip: When drilling large pilot holes, begin with a smaller bit size to create an accurate path through the material, then step up to the larger one.

Using a flathead screwdriver, screw threaded brass insert nuts into the holes you drilled in step 11; these will accommodate the hex-head connector bolts you’ll use to attach the sides of the cart in step 14.

At the ends of each crosspiece, find the center by drawing two lines from corner to corner. Repeat steps 11 and 12 to drill holes and add insert nuts at these spots.

Stand the bottom tray on a long side and the crosspieces on their ends. Lay one set of the cart’s legs over these pieces, handle recess facing down. Line up the pilot holes with the insert nuts in the tray and crosspieces. Using a hex key, twist hex-head connector bolts through the holes and into the nuts. Fit one end of the handle into the recess, and use a 1½-inch stainless-steel screw to secure it to the leg through the countersink.

Flip the cart over so that the attached side sits on the work surface. Thread the axle through the 5⁄16-inch axle hole, which is on the A leg, beneath the bottom tray of the attached side. Fit the axle hole of the cart’s second side over the axle. Line up the pilot holes, and attach the second side of the cart as described in step 14.

Slip the wheels onto the axle. Insert cotter pins through the holes at the axle’s ends, and bend their legs around the axle to keep the wheels in place. Cover the ends of the axle with the axle caps (included).

Tip: If you can’t bend the legs of the cotter pins by hand, use a pair of needle-nose pliers to get the job done.

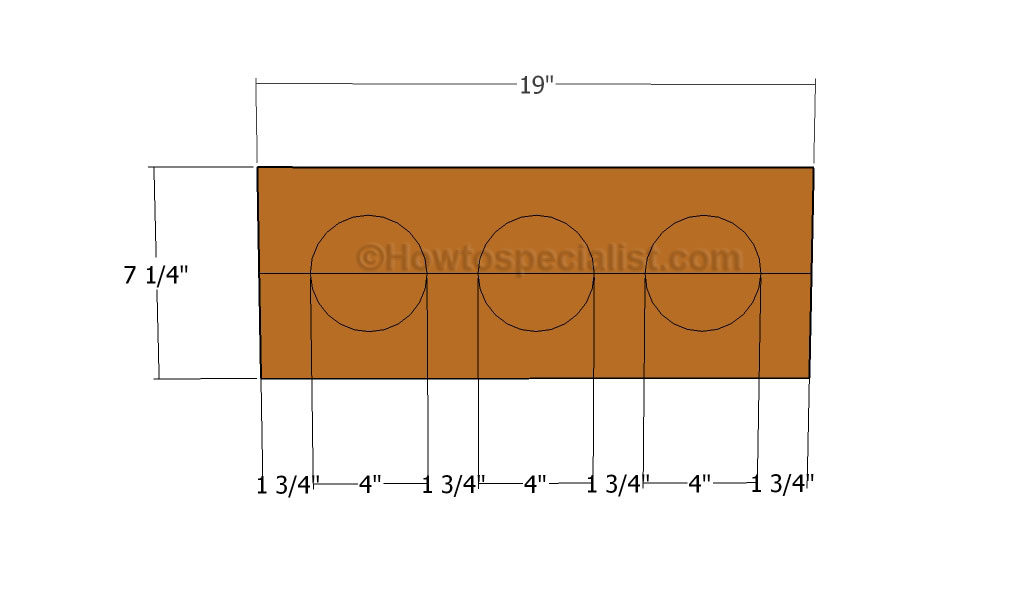

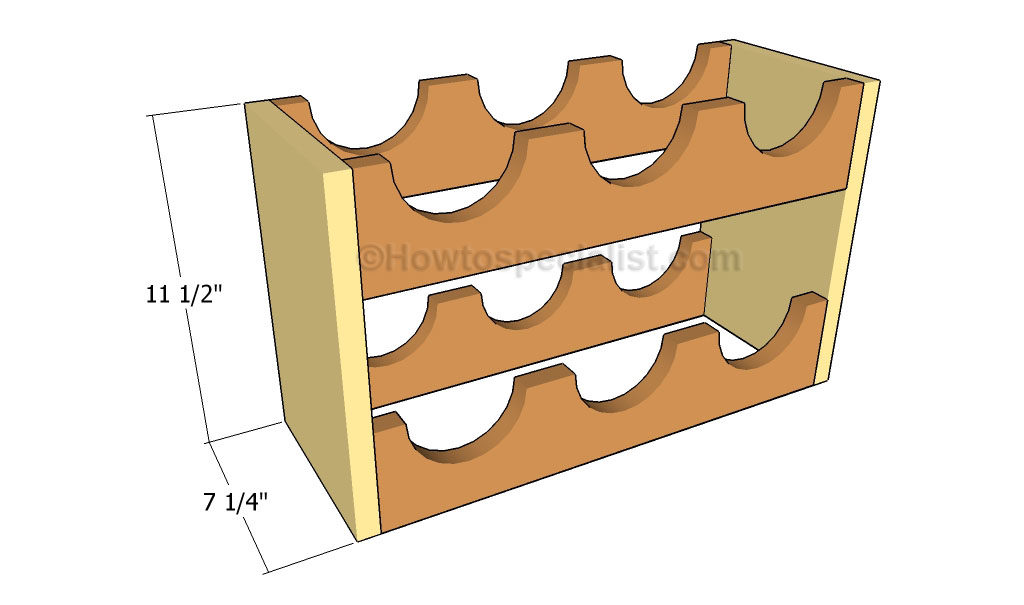

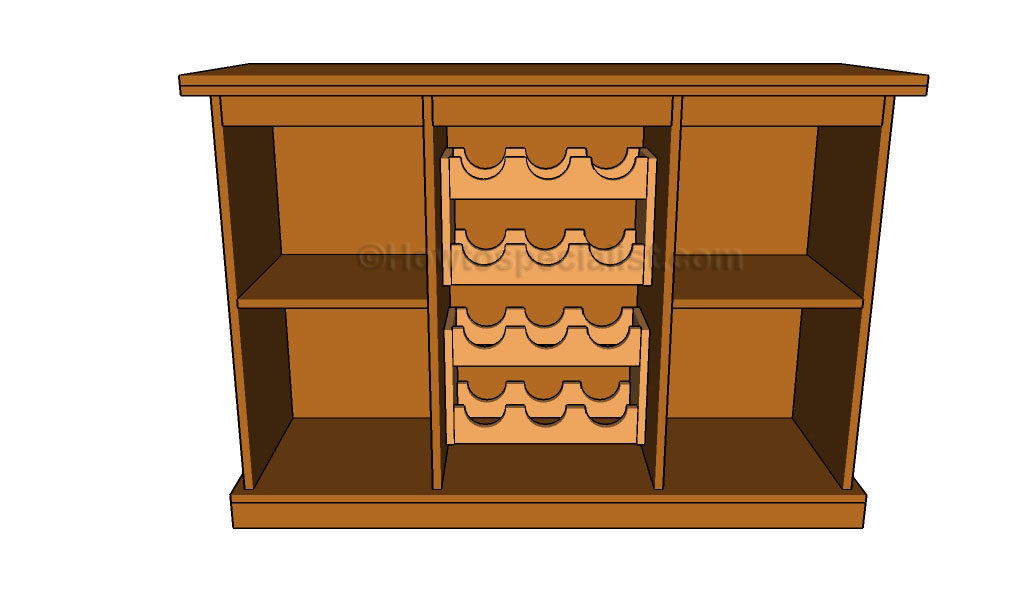

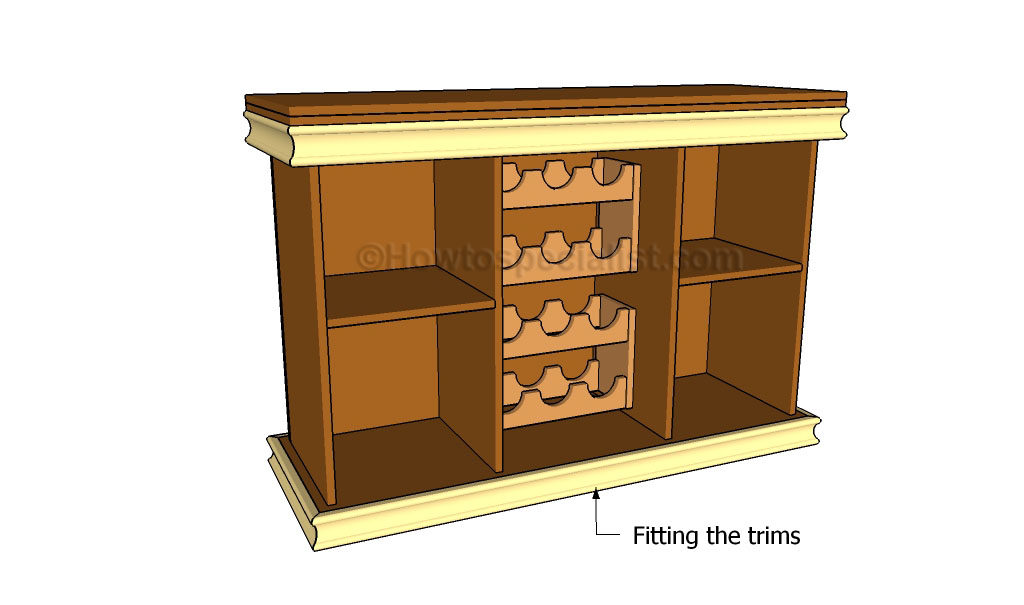

Refer to the illustration for dimensions. Cut two 1×4 long sides, two 1×3 short sides, and three 1×3 bottle spacers. Follow the process in step 4 to glue, butt, and nail the joints together. Start by attaching the edge of a long side to the end of a short side so that they’re flush at their top edges. Next, attach the edges of the spacers along the inside face of the long side, flush with its bottom edge and spaced at proper intervals (use bottles to size them). Attach the second long side to the end of the first short side and the edges of the spacers; it should be flush with the top of the short side and the bottoms of the spacers. Finish by attaching the edges of both long sides to the ends of the second short side, flush at their tops. Fit the rack onto either tray to hold bottles in place.

Tip: If you leave the cart unfinished, the cedar will weather to an attractive silvery gray—just like a beach house. If you’d rather preserve the color of the wood or bring out its red undertones, apply a clear toner, such as Penofin, annually.

The original plan is from https://www.thisoldhouse.com