Shopping List:

Wood:

- 2 – 1×2 @ 9 ft long

- 4 – 1×3 @ 8 ft long

- 1 – 1×4 @ 9 ft long

- 1 – 1×6 @ 9 ft long

- 1 – piece of half round molding @ 9 ft long

- 1 – piece of 2 1/2″ base molding @ 9 ft long

- 1 – Sheet of 3/4″ plywood (you will have quite a bit of scrap for your next project)*

- 1/4 – Sheet of 1/4″ plywood

Hardware and Supplies:

- 2 – sets of cheap-o bottom mount 20″ or 22″ drawer slides

- 2 – sets of Euro Inset Hinges

- 1 1/4″ Screws

- 1 1/4″ Pocket Hole Screws

- 5/8″ Finishing Nails

- 1 1/4″ Finishing Nails

- 2″ Finishing Nails

- Wood Glue

- Wood Filler

- Medium Grit Sandpaper

- Primer or Wood Conditioner

- Paint or Stain

Cut List:

- 2 – 1/4″ PLY @ 24 1/2″ x 16 1/4″ – Door Back

- 2 – 1/4″ PLY @ 22 3/4 x 4 1/2″ – Drawer Bottom

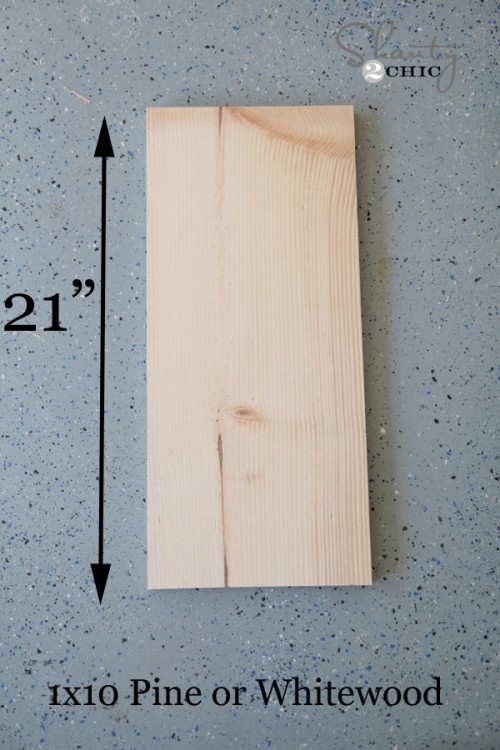

- 2 – 3/4″ PLY @ 35″ x 23 1/2″ – Side

- 1 – 3/4″ PLY @ 33″ x 23 1/2″ – Bottom Shelf

- 1 – 1×2 @ 33″ – Base Support

- 2 – 1×2 @ 35″ – Side Trim (front)

- 3 – 1×2 @ 33″ Front Trim

- 2 – 1×3 @ 19 1/2″ – Door Trim (center)

- 4 – 1×3 @ 24 1/2″ – Door Trim (sides)

- 4 – 1×3 @ 11 1/4″ – Door Trim (top/bottom)

- 4 – 1×3 @ 35″ – Side Trim (sides)

- 4 – 1×3 @ 18 1/2″ – Side Trim (top/bottom)

- 4 – 1×4 @ 3 1/2″ – Drawer Back/Inside Front

- 4 – 1×4 @ 22 3/4″ – Drawer Side

- 2 – 1×6 @ 33″ – Back Support

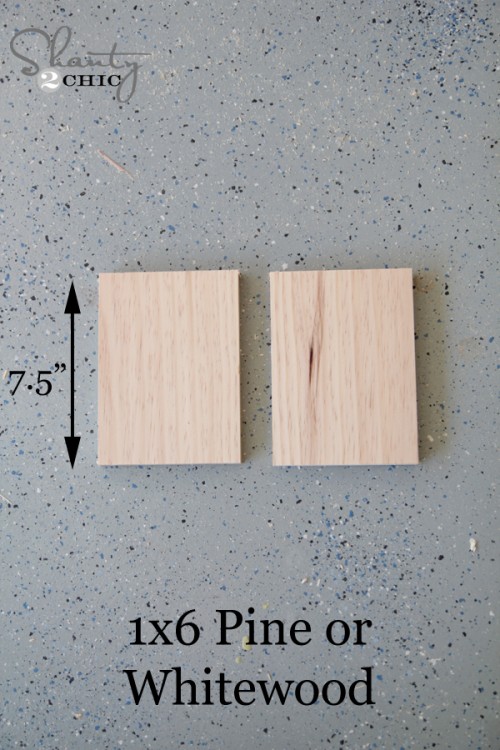

- 2 – 1×6 @ 5 1/4″ – Drawer Front

- 2 – 1×6 @ 23 1/2″ – Drawer Side Support

- 1 – 1×6 @ 20 1/2″ – Fake Drawer Front Base molding and half round cut to fit

General Instructions:

Make sure to re-measure and check for square after every step. Sometimes when building your measurements can be off very slightly, and it’s important for this plan that your numbers are exact. (Especially when working with doors and drawers!) Measure your available space and purchase your sink before building this plan to make sure that it will fit.

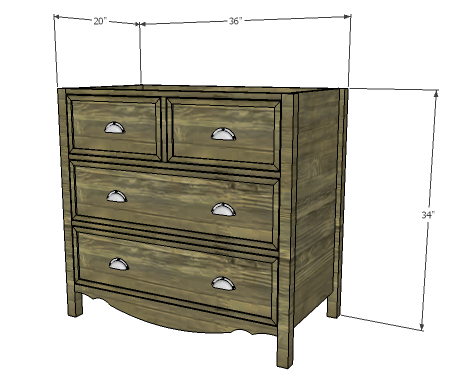

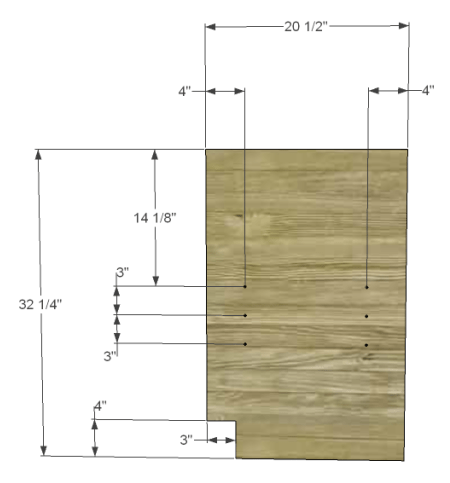

Step 1:

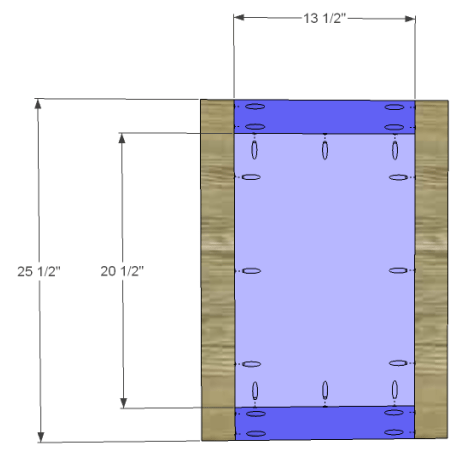

Cut plywood as shown above. My mock-up is based on a full 4′x8′ sheet, but this project is much more ideal if you are able to use up some plywood scrap for the 1/4″ piece.

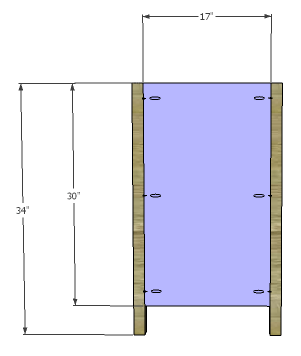

Step 2:

Attach 1×3 trim along the outside edge of of your plywood with 1 1/4″ finishing nails and glue, leaving a 1 3/4″ gap between the base and the bottom of your lowest piece of horizontal trim.

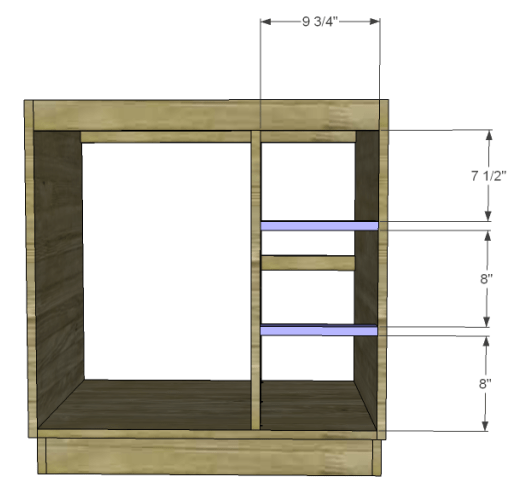

Step 3:

Attach your side trim (front) to the side of your base with 1 1/4″ finishing nails and glue. Repeat steps 2-3 to create the other side, remembering to put the side trim (front) on the opposite side of the other panel. (The side with the trim will be the front of your vanity.)

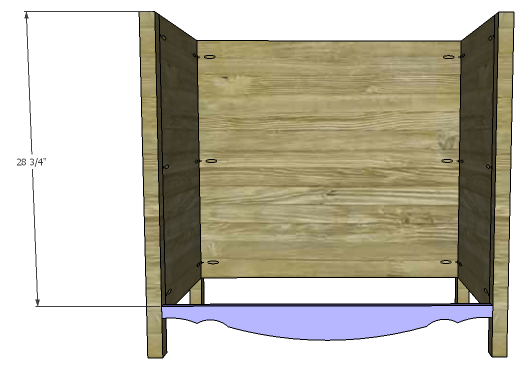

Step 4:

Attach 1×6 and 1×2 back and top supports with your Kreg Jig using 1 1/4″ screws and wood glue. For the top of the back section, add the 1×2 first to get the positioning of your 1×6 right underneath it. Attach these two pieces together with 1 1/4″ screws, remembering to countersink your holes. In addition to the kreg screws, I also attached the 1x2s from the outside with 2″ finishing nails to prevent the board from rotating.

Step 5:

Attach the bottom shelf with your Kreg Jig and 1 1/4″ pocket hole screws, making sure that it’s level. The back of the plywood should fit underneath your base support 1×6.

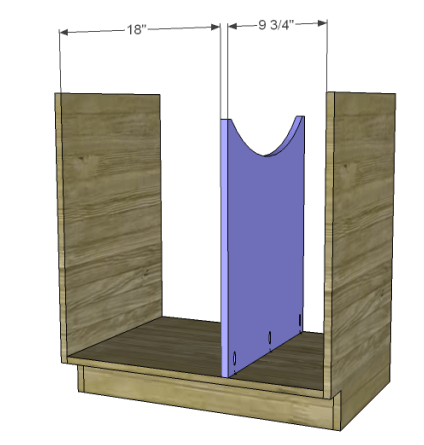

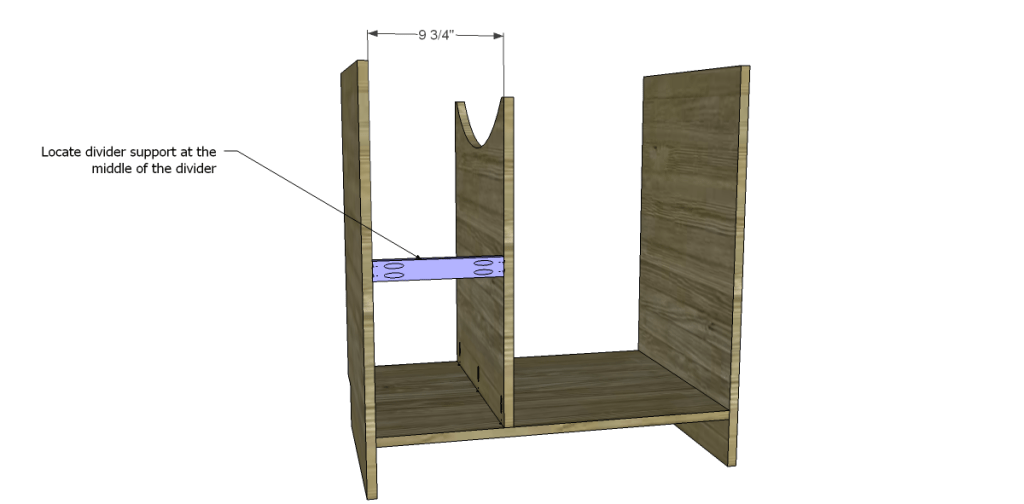

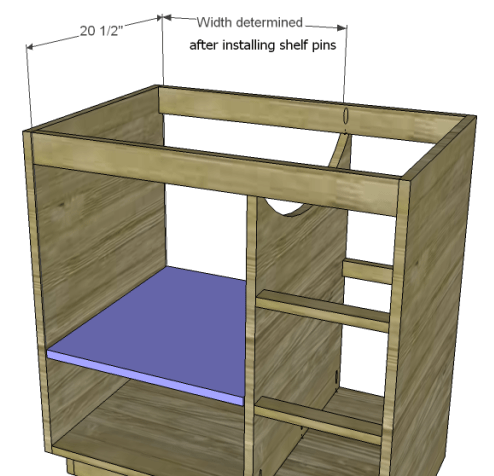

Step 6:

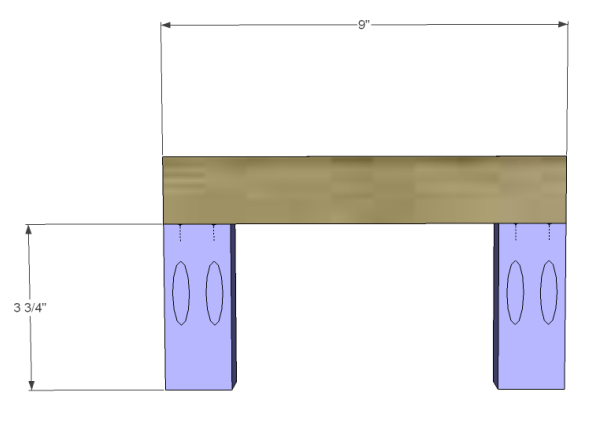

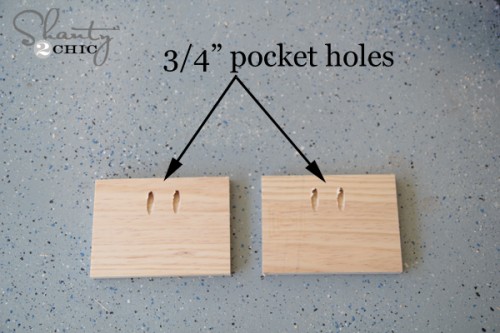

Join the fake drawer front to your drawer side supports using your Kreg Jig before attaching it to the inside of the console. There should be a 5 1/2″ gap on either side of the side supports when placed inside the vanity. Kreg Jig the drawer side supports to the 1×6 back support of the vanity using 1 1/4″ pocket hole screws. Attach the top of the fake drawer front to the 1×2 top support using your Kreg Jig. Depending on the size of your sink, you may have to notch out your 1x6s to make room for it. Since my vanity had to be smaller to fit the space, I had to do this. I used my jigsaw to cut out large, rounded rectangles to make room for the sink, making sure to keep the bottom at least 2″ high at all times to allow for future drawer slides. If you need this step, make sure to do it first, before attaching them to your fake drawer front. Since this step is a bit complicated, here are a few additional pictures to help.

Side view of the notched out 1×6 drawer supports to make room for the sink.

Front-ish view of the vanity, showing the notched boards and kreg screws into the back 1×6 support

View from behind the vanity showing the kreg screws on fake drawer front to the 1×2 top.

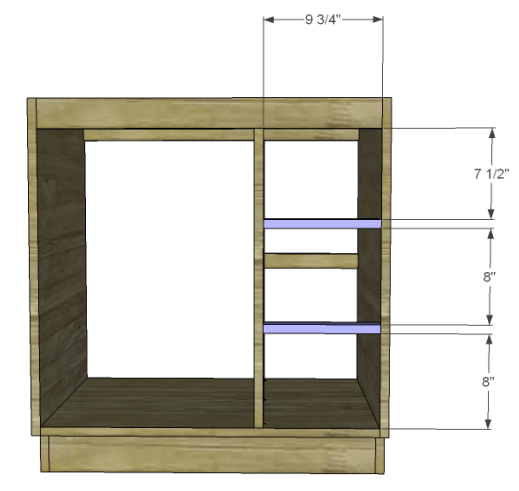

Step 7:

Attach 1×2 front trim underneath your fake drawer to the sides of your vanity using your Kreg Jig. Use 2″ finishing nails to give it some extra support on either side and 1 1/4″ finishing nails to attach it to your fake drawer. Attach base trim to the bottom shelf using 1 1/4″ finishing nails and wood glue.

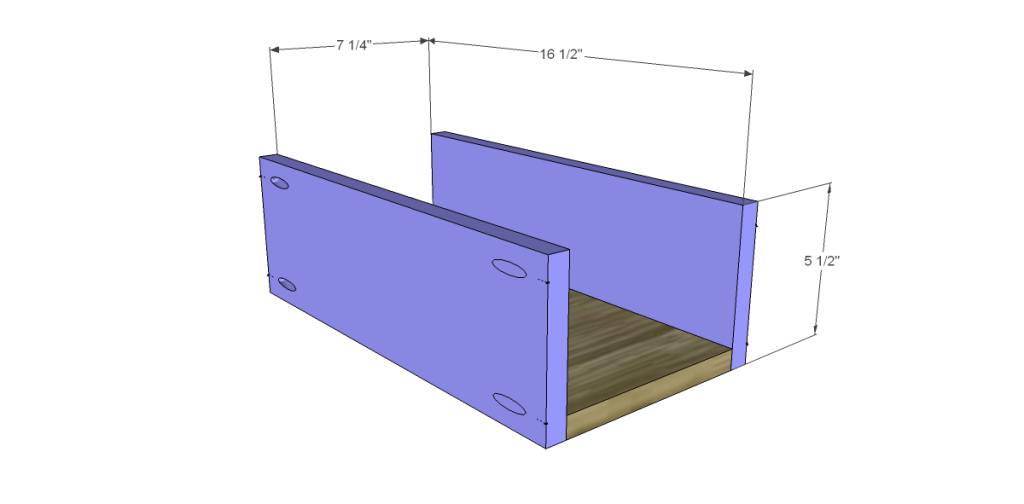

Step 8:

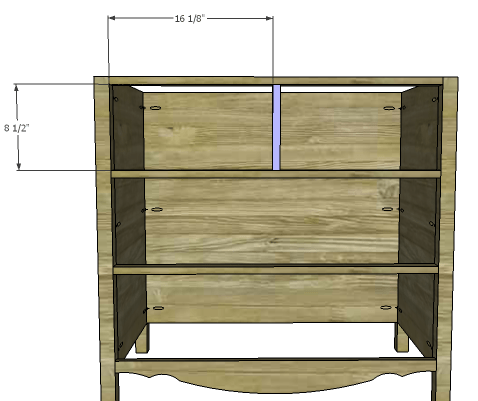

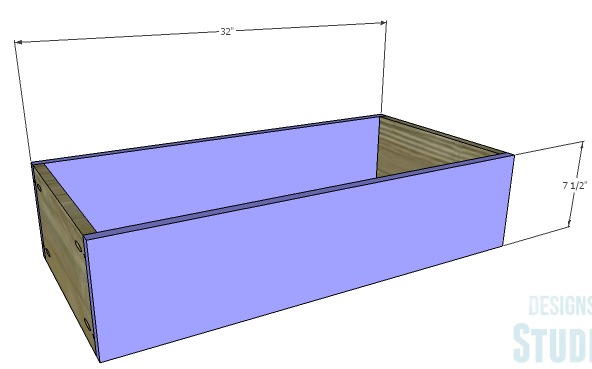

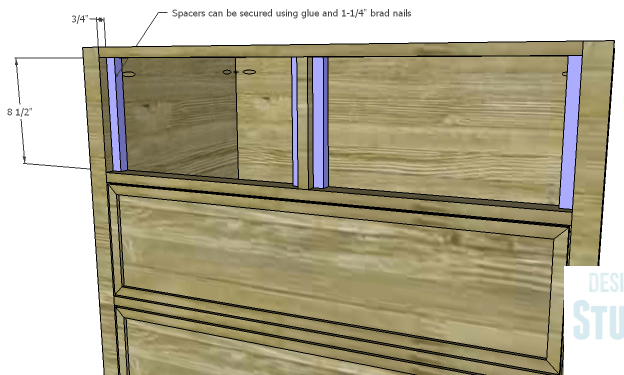

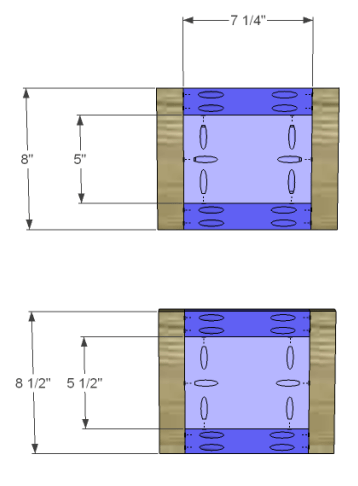

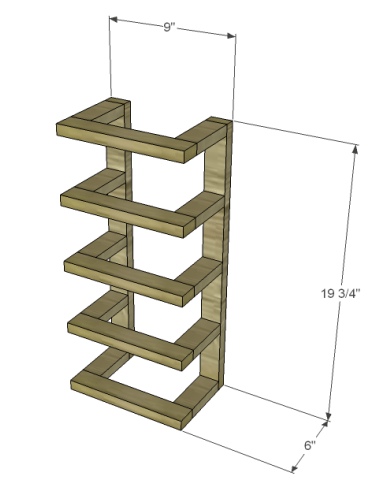

Build your drawer as shown above using your Kreg Jig and 1 1/4″ finishing nails. (My drill wasn’t big enough to get into the small spaces, so I Kreg Jig-ed one drawer front/back piece to each side and then used 1 1/4″ finishing nails to attach the two pieces like a puzzle. Attach the 1/4″ plywood base to the bottom of each drawer using 1 1/4″ finishing nails and glue.

Step 9:

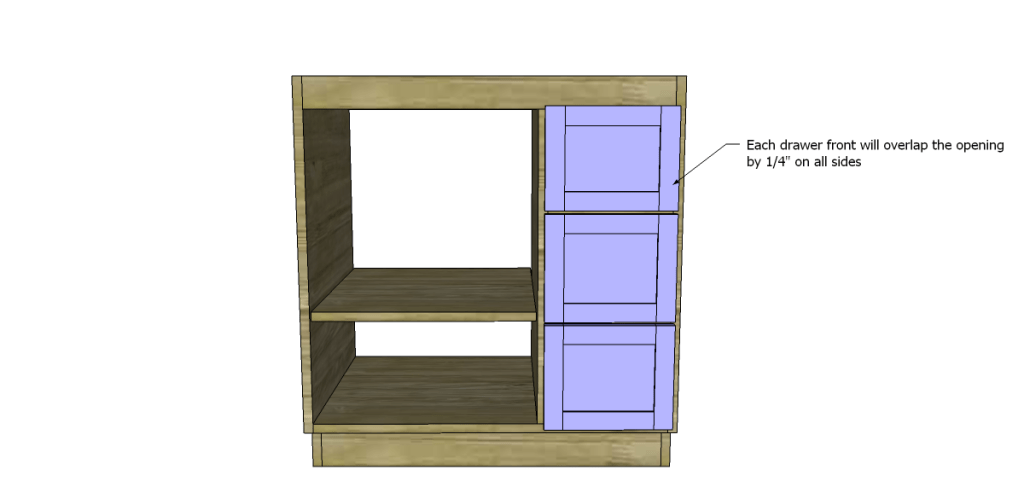

Attach your drawer slides as shown above to both the drawer and the inside of both the right and left sides of the vanity.

Step 10:

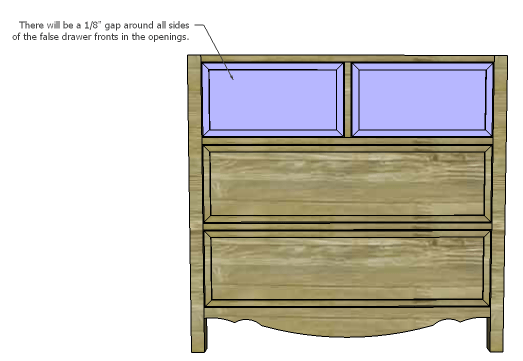

Center the fronts of your drawers into the opening, leaving 1/8″ around all sides. When it’s in place, attach with 1 1/4″ finishing nails.

Step 11:

Attach 1×3 door trim to the your plywood from the back with 5/8″ finishing nails and glue. There should be a 4 3/8″ space on either side of your center door trim between that and the insides of your side trim. (For a stronger hold, you could kreg jig your 1x3s together from the back prior to attaching them to the plywood.) Attach each door to the inside of the vanity using your inset hinges, making sure to leave a 1/8″ gap on all sides.

Step 12:

Attach doors to the vanity using your inset hinges. Put your vanity face down and place your doors where you would like them to go, leaving 1/8″ along all sides.

Align hinges along the edges and screw in a few of the screws. (I do two screws per hinge on the door side and two on the frame.)

Stand your console back up and test how the hinges work. If they’re lining up where you want them to, screw in the other half of the screws.

Close your doors and enjoy your new hinges!

Step 13:

Attach base molding as shown, mitering your corners. I’ve attached rough measurements, but make sure to measure your base prior to cutting – every handmade project is just a little different, and those 1/8″s count!

The original plan can be found at http://www.oldpaintdesign.com

[email_link]

[email_link]

Step 4:

Step 4:

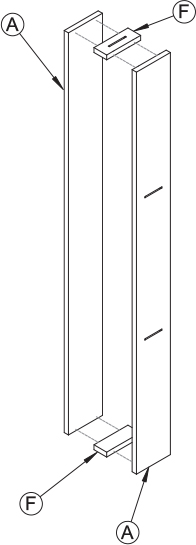

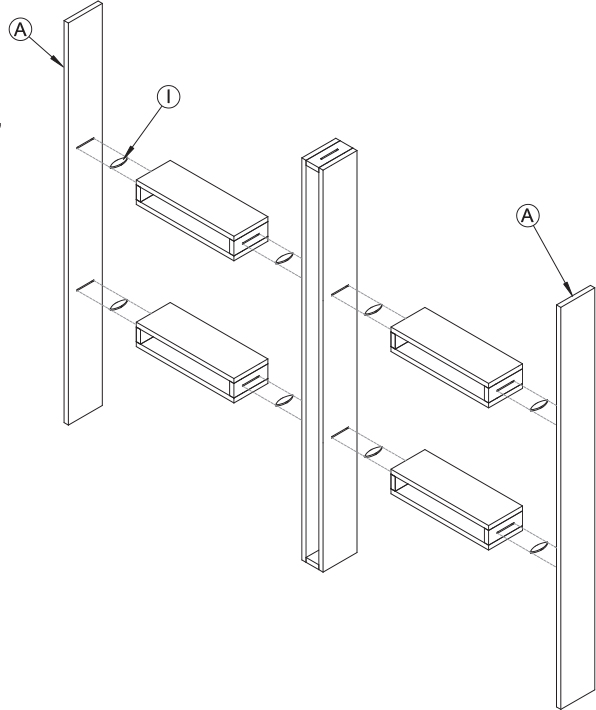

Assemble each of the four horizontal modules by gluing and nailing two spacers F between two horizontal sides C, one spacer at each end. All surfaces with slots should be facing outwards.

Assemble each of the four horizontal modules by gluing and nailing two spacers F between two horizontal sides C, one spacer at each end. All surfaces with slots should be facing outwards. Fasten two horizontal modules between a side A and the vertical module, then do the same on the other side. Insert more spacers into the vertical module as needed, to prevent its sides from bending inwards. Hold in place with clamps and go straight on to the next step.

Fasten two horizontal modules between a side A and the vertical module, then do the same on the other side. Insert more spacers into the vertical module as needed, to prevent its sides from bending inwards. Hold in place with clamps and go straight on to the next step. Apply glue to the slots in top / bottom G and to the ends of sides A. Insert the biscuits into the slots, then nail top / bottom G to sides A.

Apply glue to the slots in top / bottom G and to the ends of sides A. Insert the biscuits into the slots, then nail top / bottom G to sides A. Glue and nail panel E to the back of the shelves.

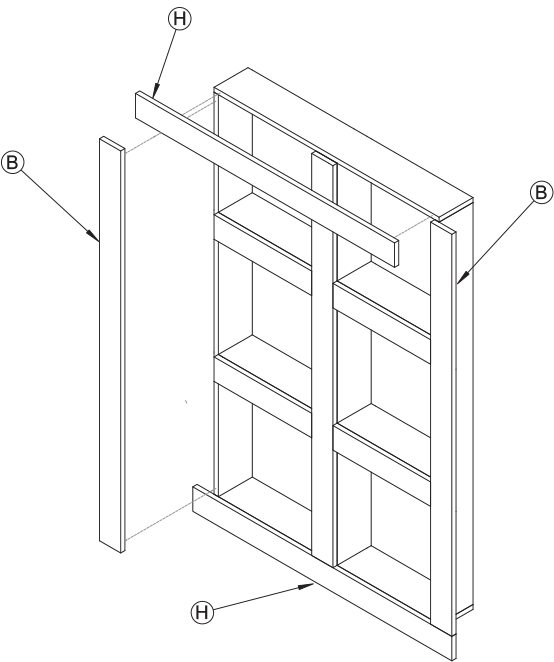

Glue and nail panel E to the back of the shelves. Glue and nail one vertical facade B to the front of the vertical module and fasten short horizontal facades D to the horizontal modules in the same way.

Glue and nail one vertical facade B to the front of the vertical module and fasten short horizontal facades D to the horizontal modules in the same way. Insert the shelf unit into the wall opening, resting it on the bottom girt. Check for level, then screw into the studs.

Insert the shelf unit into the wall opening, resting it on the bottom girt. Check for level, then screw into the studs. Glue and nail the two remaining vertical facades B and the two long horizontal facades H to the edges of the shelf unit in order to form a frame to conceal the cuts in the drywall. Fill the holes and apply a coat of primer. Paint.

Glue and nail the two remaining vertical facades B and the two long horizontal facades H to the edges of the shelf unit in order to form a frame to conceal the cuts in the drywall. Fill the holes and apply a coat of primer. Paint.