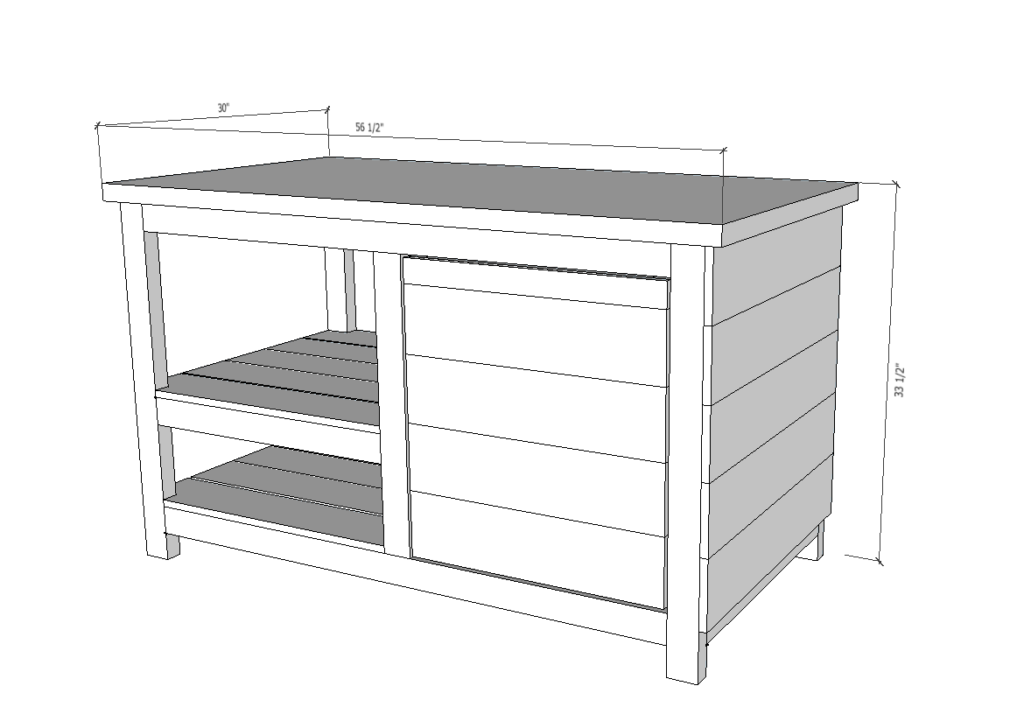

BBQ Grill and Cooler Table

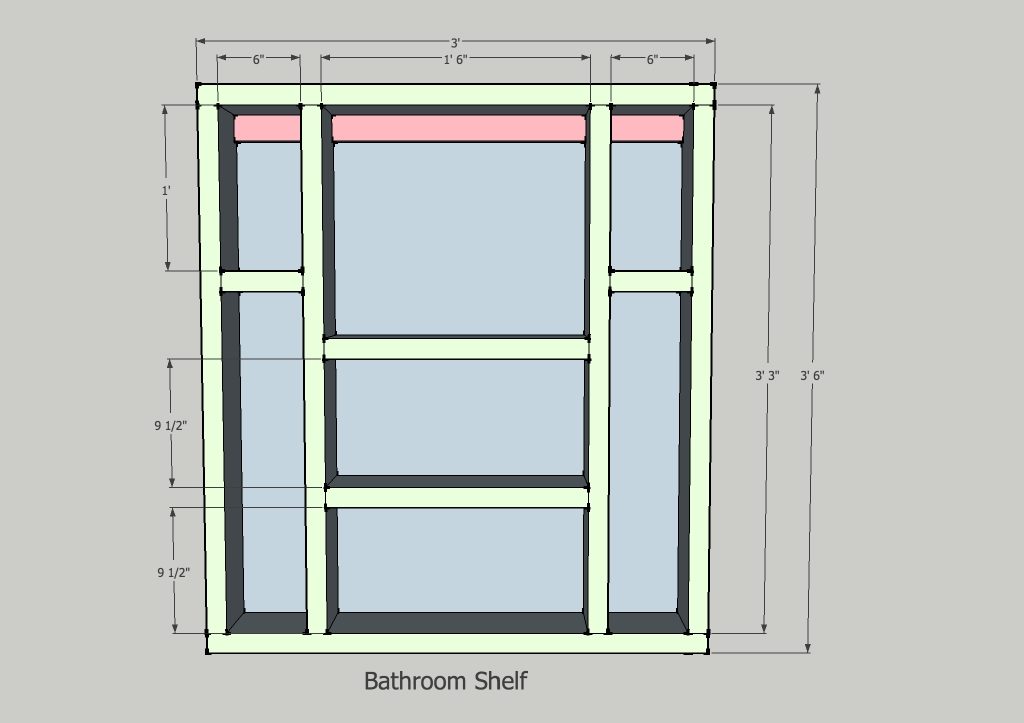

Today I’m going to show you How to Build a Patio Cooler and Grill Cart Combo. The grilling season is upon us! The cool weather is making an exit and the heat, BBQ, and outdoor parties are here. Two things I’ve been thinking of building are a patio cooler and a grill cart. Since my back deck is not huge I decided to kill two birds with one stone and show you guys how to make a DIY patio cooler box and BBQ cart in one.

The project is made from cedar to withstand the elements and give it a nice classy look. The heart of the cooler box side is 48 qt cooler with plenty of capacity for your parties. The grilling side has a storage compartment and hooks to hold all your BBQ accessories. The lid for the storage box is flush with no hinges or handles giving you a 22″ x 20″ landing space for food and other barbecue fixings. The assembly is easy and straight forward so read ahead and get ready to get your summer outdoor entertaining game on point!

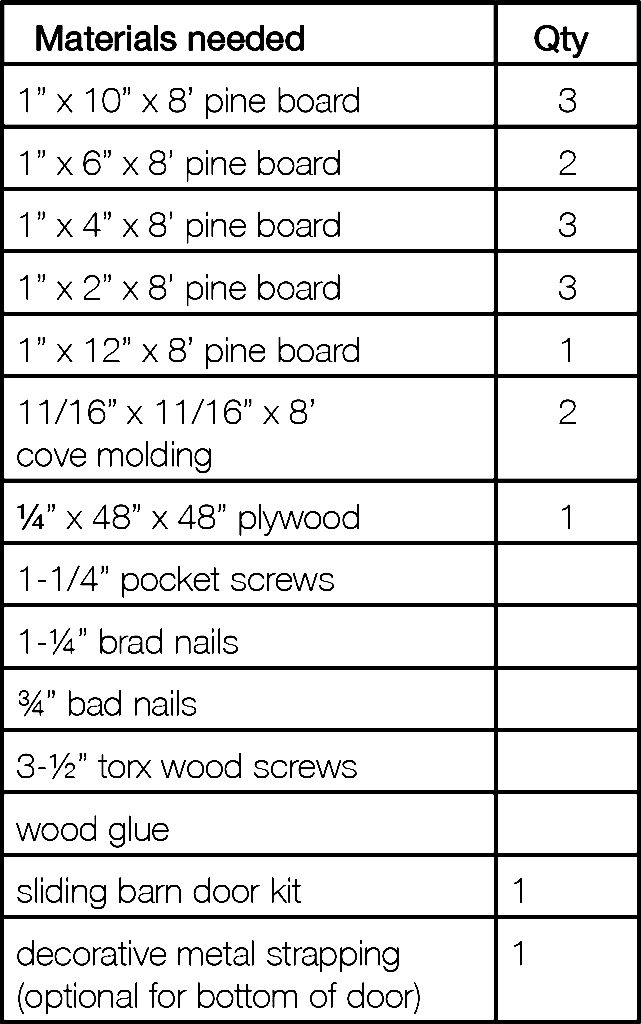

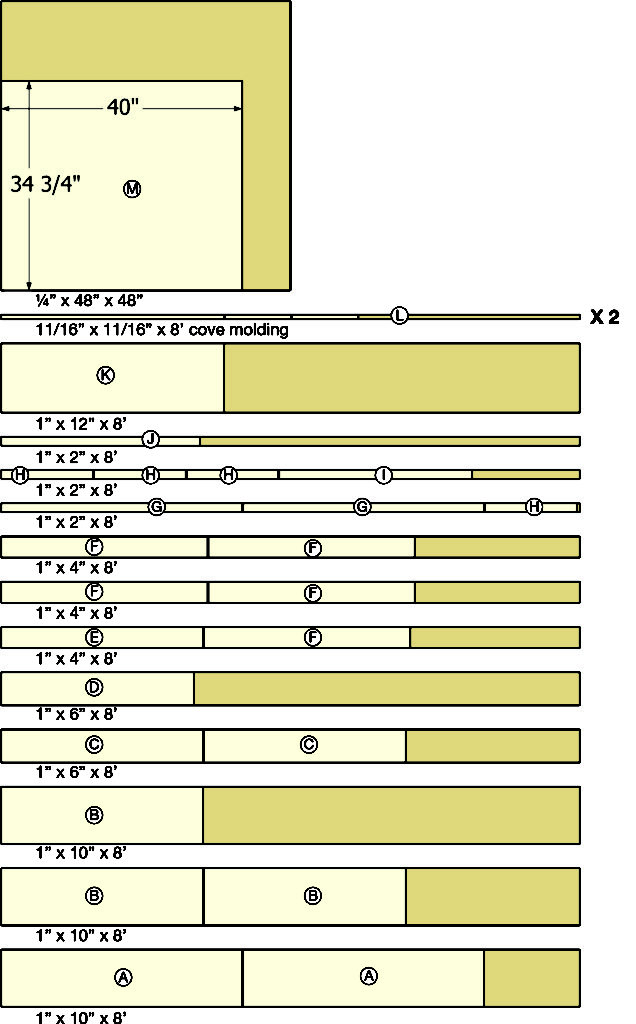

- (13) 12′ 1×4 cedar boards

- 1-1/4″ Pocket Hole Screws

- 1-1/4″ Exterior Screws

- 48qt Cooler

- 3″ utility hinges

- Front handle

- Bottle Opener

- Single Hooks

- Hose Bib

- (2) 1/2″ Male PVC Adapter

- 1/2″ PVC Pipe

- 1/2″ PVC Nut

I built the cooler box and grilling station entirely out of 1×4 cedar. My local lumber supplier had 12′ boards that were rough on one side and I was able to get them for half the price of what you would pay at the big box store for the cedar 1x4s. If this is an option for you then you can save some significant money going this route.

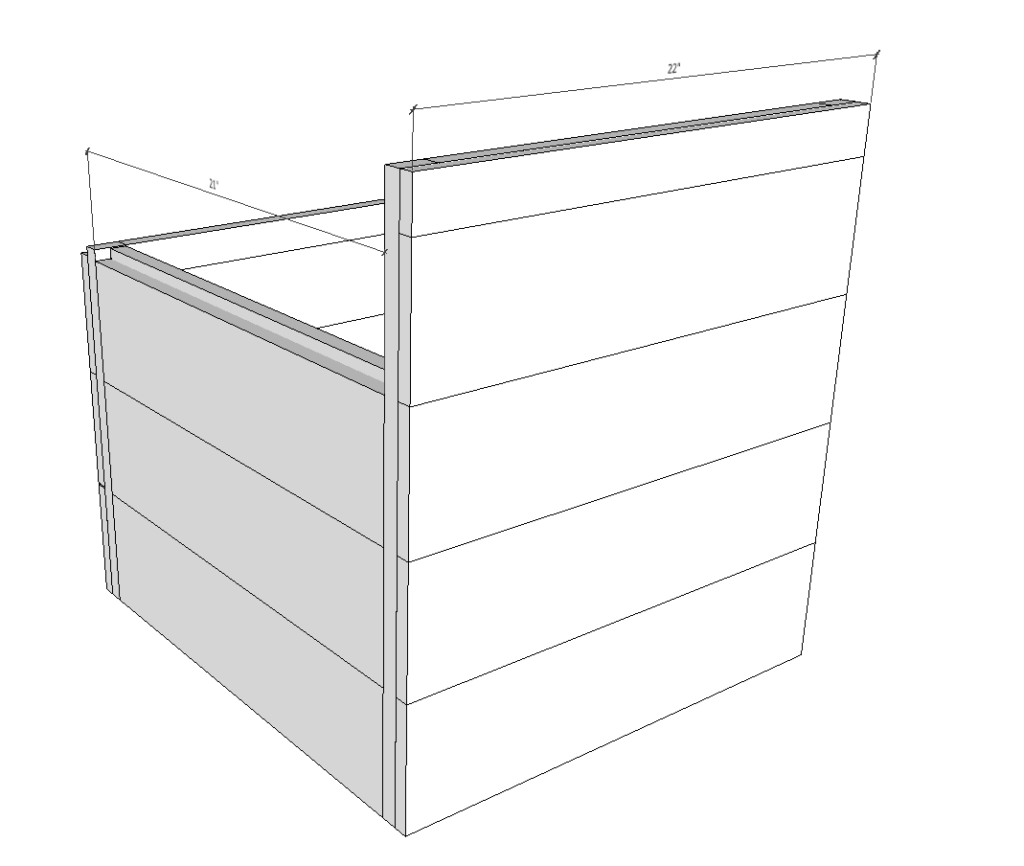

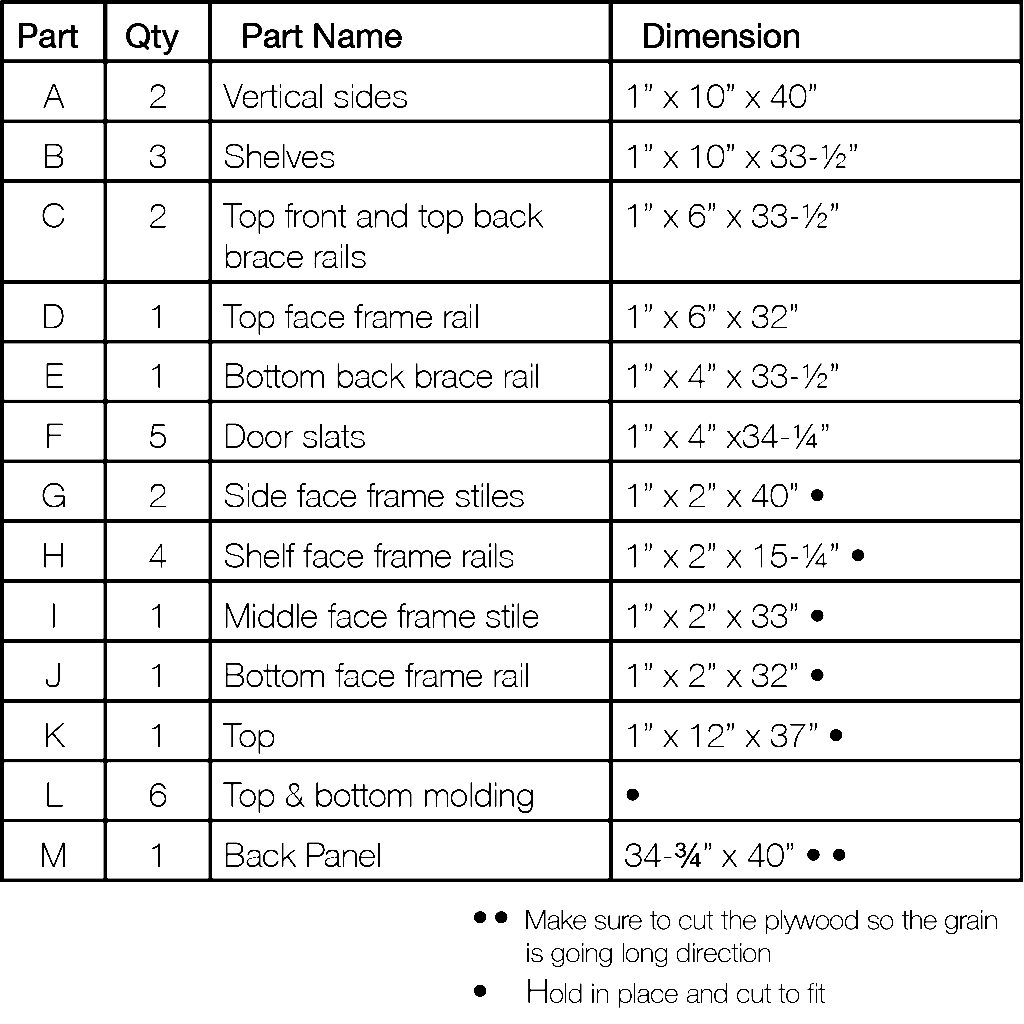

You’ll start by building the top frame based on the size of your cooler. The top of my cooler was 23-3/4″ x 13-1/2″. If your cooler is a different size then you’ll need to adjust the top frame accordingly and see if you need to adjust the base as well.

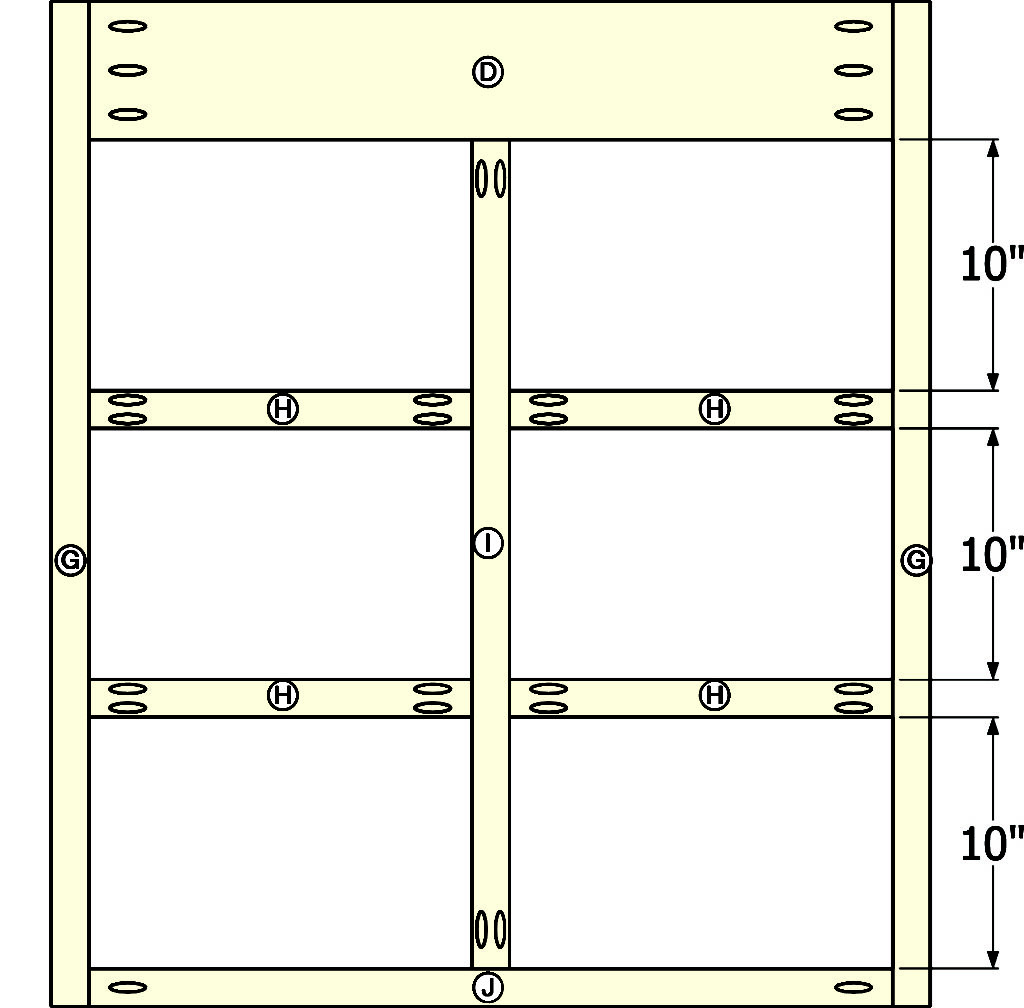

Cut 2 boards to 50″ for the long top frame pieces and 3 boards to 13-1/2″ for the short top frame pieces. Drill pocket holes in the ends of the short pieces and assembly with 1-1/4″ pocket screws. This will give a 15-3/4″ opening for the grilling storage box.

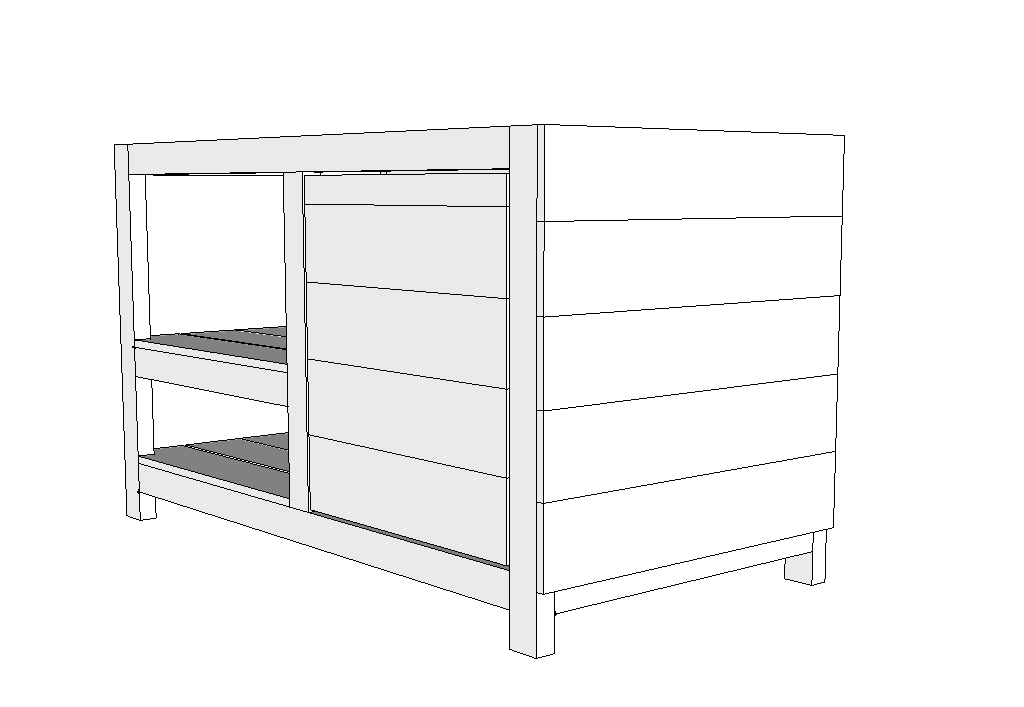

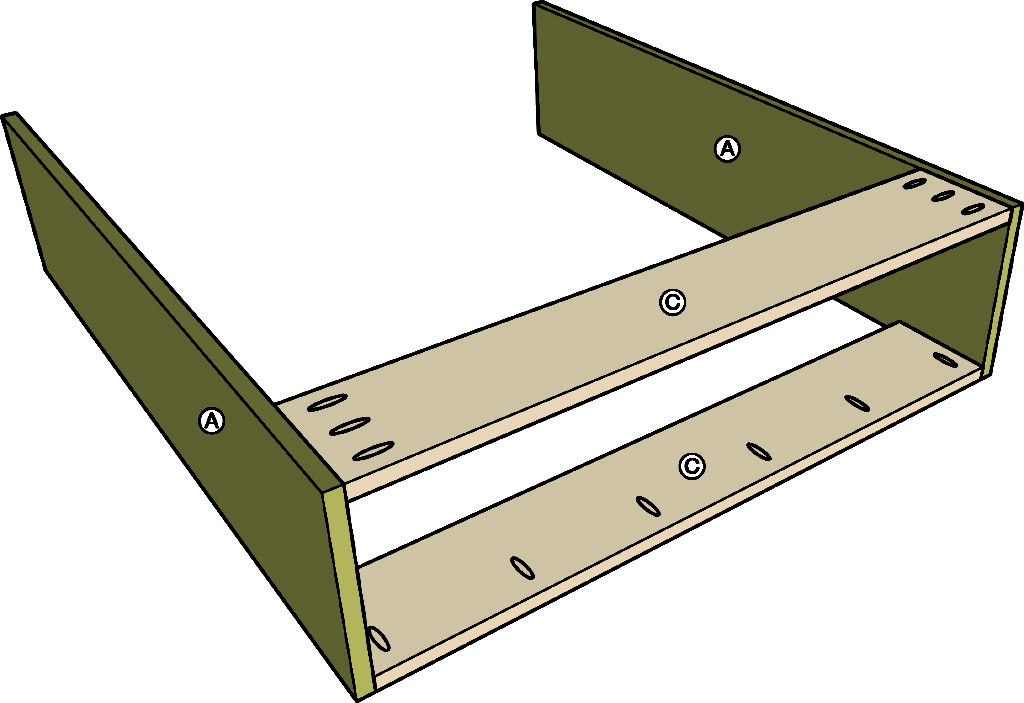

Cut 8 boards down to 38-1/4″ long for the legs. Rip down 4 of these boards to narrow leg pieces at 2-3/4″ wide. Use a pocket hole jig to drill pocket holes in the 2-3/4″ pieces in the top 13″ of the leg and another hole 2″ up from the bottom.

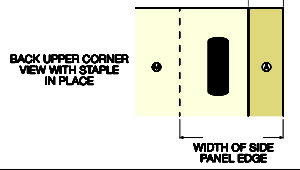

Join the narrow leg pieces to the wide pieces glue and 1-1/4″ pocket hole screws on the top and bottom. In the gap where there are no pocket holes, use clamps to hold the joints tight. Make two legs with the narrow pieces on the right side and two with the narrow pieces on the left side. This lets you have the wide face of the legs showing on the front and back of the cooler.

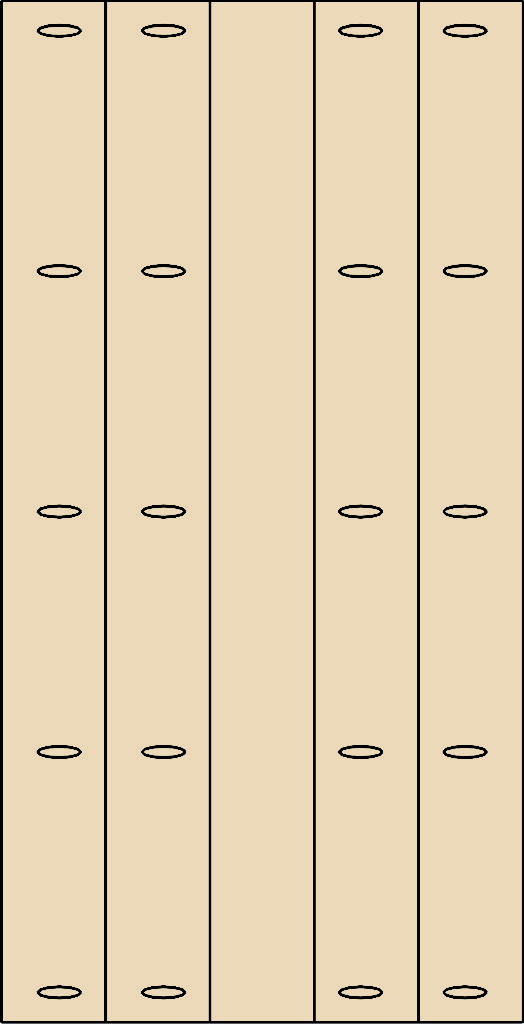

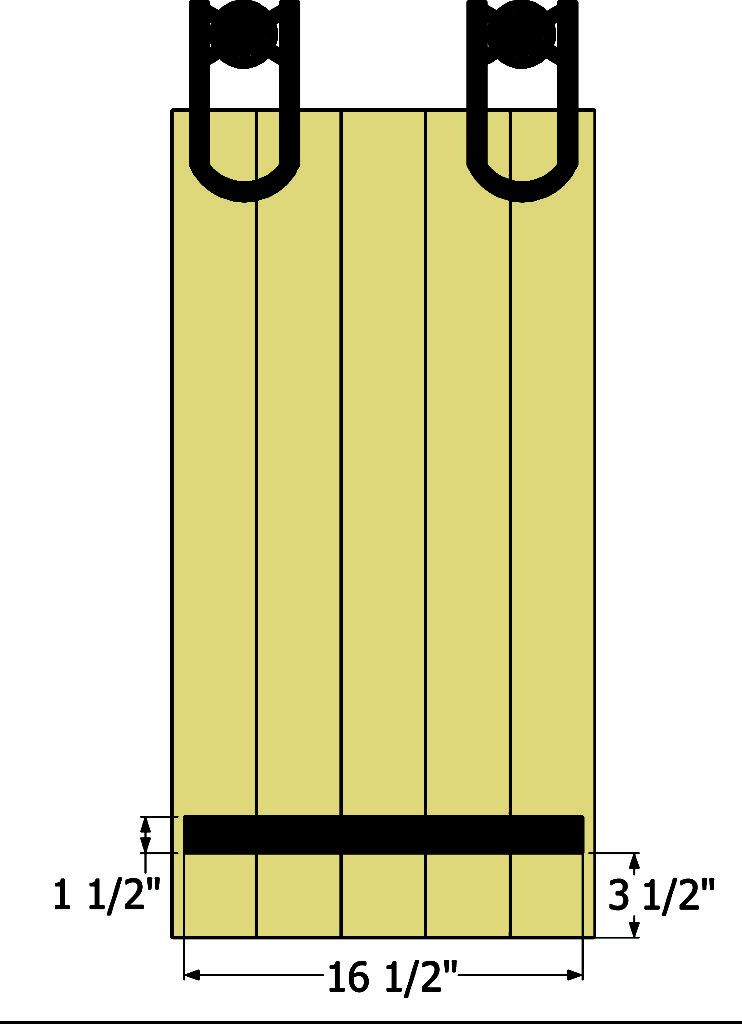

Cut 8 pieces of side cladding to 16-1/2″ long. Use a trim router to route a 1/16″ 45 degree chamfer on the outer edges of each board. This will give the boards a nice beadboard look when butted together.

Lay two legs down and starting from the top, attach 4 side cladding pieces to the legs with two 1-1/4″ screws on each side of each board. Repeat this process with the other 2 legs to form 2 side assemblies.

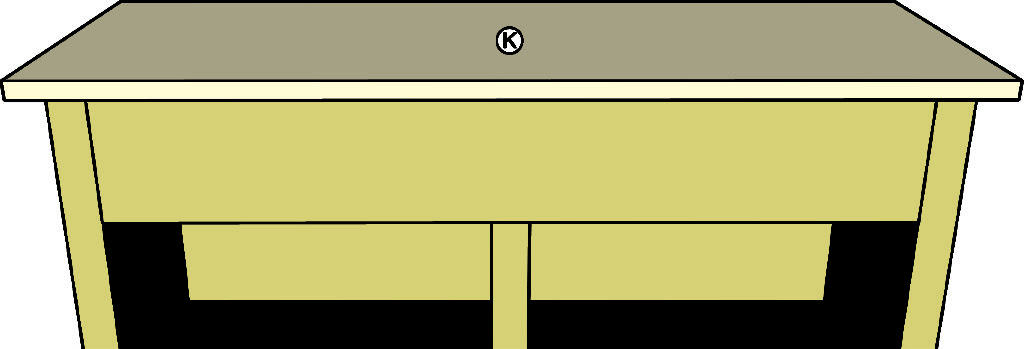

Cut 4 pieces of front cladding and 4 pieces of back cladding to 44-1/2″ long, and route a chamfer on the long edges just like the side cladding. Side the side assemblies on edge and starting at the top, attach the front cladding to the sides with 1-1/4″ screws.

Flip the assembly over and now attach the 4 back cladding pieces to the sides. Now you have the base of your patio cooler and grill cart combo!

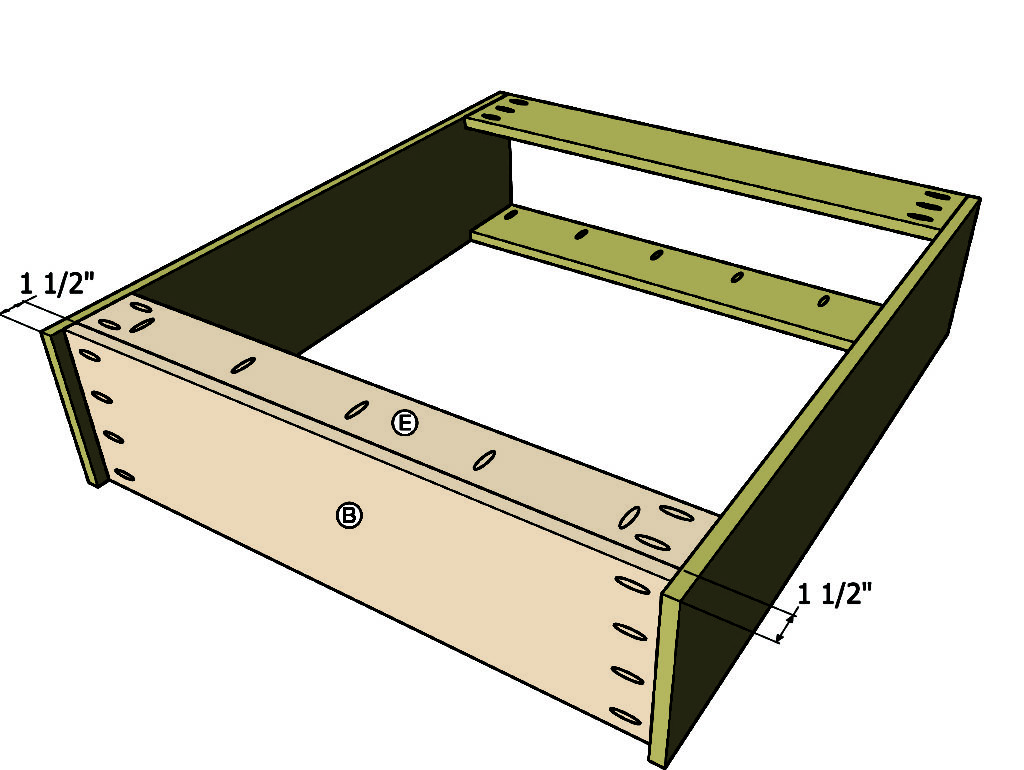

Cut two 3/4″ x 3/4″ top front cleats 14″ long and one top side cleat 11″ long. Predrill holes on the bottom for attaching the top frame later. Secure the 11″ cleat to the middle of the right side flush with the top and secure the 14″ cleats to the front and the back 1-1/2″ away from the right side.

Attach two 1″ wide 14″ long cleats to the inside of the front and back walls, 18″ from the right side. Cut four 15″ wide storage divider boards and glue and screw them to the cleats to create the storage bay.

Cut and install two 17-1/4″ cleats to the front and back of the storage bay. Put them 3/4″ up from the bottom of the bay then attach five 15″ storage bay bottom pieces to the cleats with screws from underneath. The middle board will need to be trimmed to fit.

Attach the top frame to the base with pocket hole screws on the cooler side and with 1-1/4″ screws through the cleats in the storage bay. Use glue on all the top surfaces for a good hold.

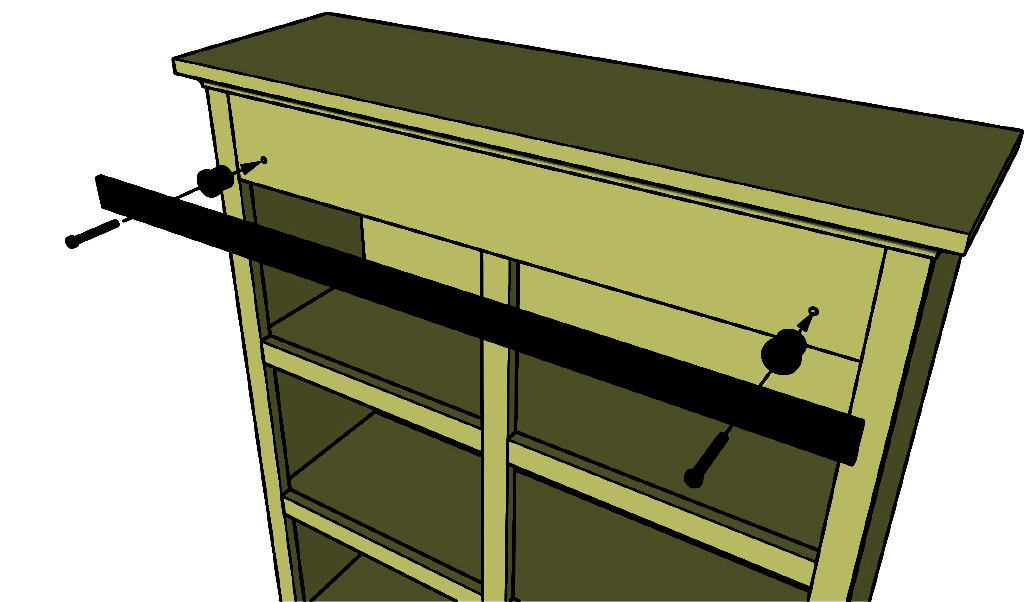

Cut two 46″ long 1″ wide shelf stretchers and eleven 16-1/2″ shelf slats. Attach the slats to the stretchers with glue and a brad nailer. For consistent spacing start with the outer slats and then secure the middle slat. From there fill in the gaps spacing the slats 3/4″ apart.

Test fit your cooler in the opening and remove the cooler drain plug. Reach a marker through the cooler drain and mark a spot on the left side of the patio cooler. Drill a 1-1/4″ hole in the side for the plumbing fittings.

Flip the grill cart combo over and put the cooler in place. Secure the cooler by installing three 15″ cooler supports into the front and back with 1-1/4″ pocket screws.

Flip the cooler back over and cut four 15-3/4″ long storage bay lid pieces. Put a chamfer on the boards with the trim router like the body cladding. Drill a 1″ hole in the middle of one board and chamfer the top edge of the hole.

Cut two 13-1/2″ by 1″ wide lid battens. Line the lid boards up together with the board with the hole at one end and fasten the boards together using the battens, glue and 1-1/4″ screws.

Make 4 small 1-1/2″ x 2″ storage lid tabs. Round one corner of the tabs and install them in the top corners of the storage bay with glue and brad nails into the top corners of the storage bay.

Build the frame around the lid by based on your own cooler measurements. The sides should be 3/4″ taller than your lid. I cut two lid front/back pieces to 25-1/4″ by 2″ and two side piece 13-1/2″ by 2″. Join the lid frame with 1-1/4″ pocket hole screws.

Cut 3 lid support cleats to 13-1/2″ by 1″ and attach them to the front and back with pocket holes. Place the outer cleats so they are directly over the side ridges on your lid that mate with the cooler body. You’ll be screwing into the lid later and don’t want the screws to pop through the underside of the lid.

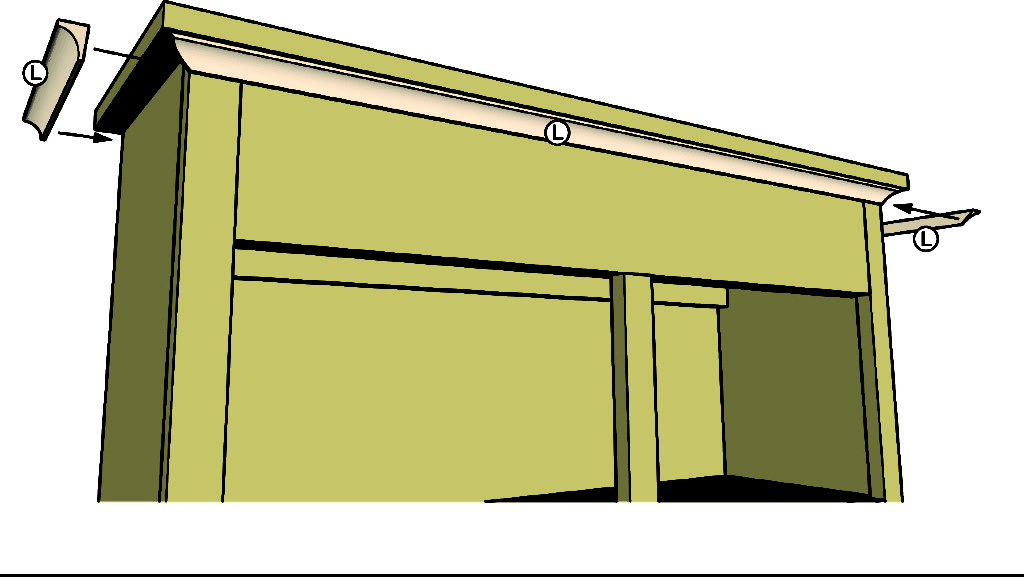

Make 5 lid top pieces out of 25-1/4″ boards. Route the 45 degree chamfers on these boards just as the others. Layout the boards on the top and cut the center piece to width to fit. Use super glue and temporarily affix the full size boards to the edges of the frame.

Flip the lid over and permanently attach the lid boards to the cleats with 1-1/4″ screws.

Flip the lid over again on top of the cooler. Now secure the top to the cooler lid with 1-1/4″ screws through the outer cleats into the lid. Attach the center board with wood glue on the center cleats and super glue on the outer edges. The super glue will bond quickly and the wood glue will give a long lasting hold. Assembling the lid this way give you a super clean look with no nail or screw holes…SCORE!

Remove the drain from your cooler and keep the washer on the inside. Get two 1/2″ PVC male threaded adapters, a length of 1/2″ PVC, a 1/2″ nut and a hose bib for the outside of the cooler.

The length of the PVC pipe will vary per installation. Cut a hose bib mounting block to 3-1/2″ by 3-1/2″ and drill a 1″ hole through it for the male adapter. You may need to drill a larger hole with the collar if the fitting won’t go through. Glue up the final PVC parts and install them on the hose bib and mounting block. Put wood glue around the mounting block and insert the assembly into the cooler and lock in place using the nut in the cooler.

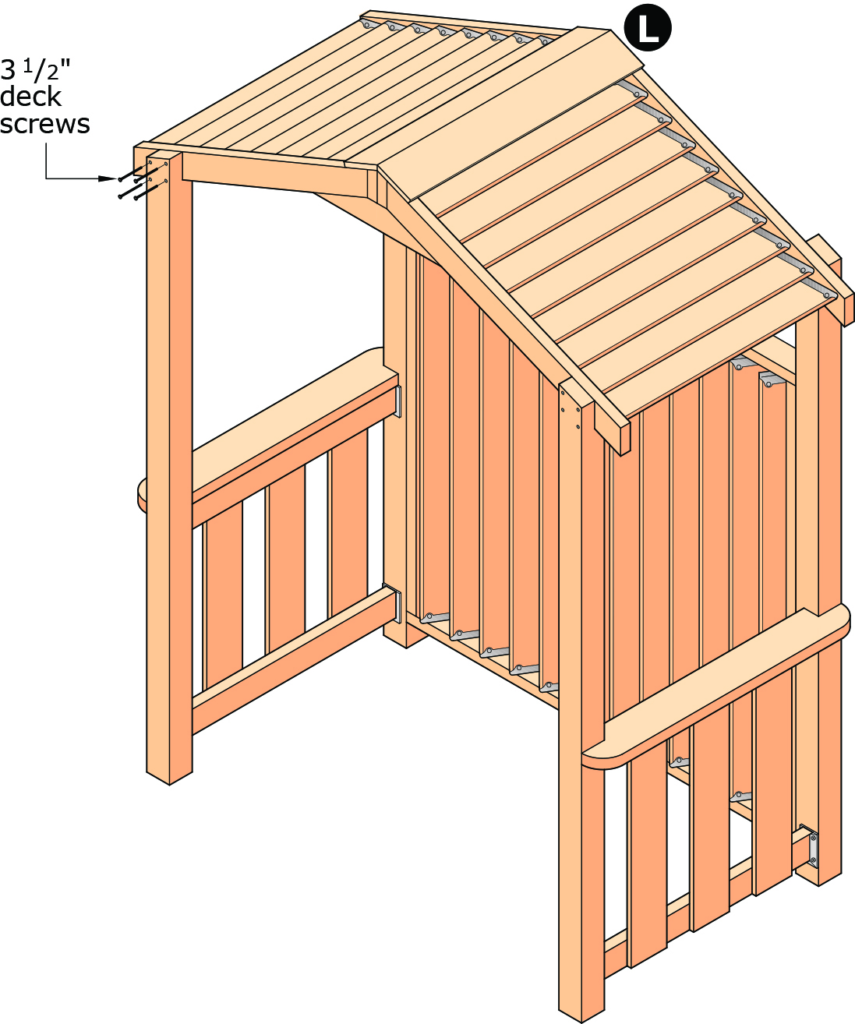

Sand everything down to 150 grit and apply your finish at this point. I used a Spar Urethane made for outdoors.

After the finish is dry, install the lower shelf so the bottom is 2-1/2″ up from the floor. I would recommend turning the patio cooler on it’s top to do this vs. laying it on its back like I did

The cooler lid gets 3″ utility hinges and a handle on the front.

I added a bottle opener on the front and 2 hooks on the grilling side of the cart as well.

I put my inserts for my STOK Quattro grill into the storage side and it worked great to hold them all. I just put some little dividers in there to keep them separated.

Alright, you’re all finished up! Put the patio cooler and grill cart combo out on your deck and let the good times roll this summer.

The original plan can be found at http://fixthisbuildthat.com